) SYSTEMS

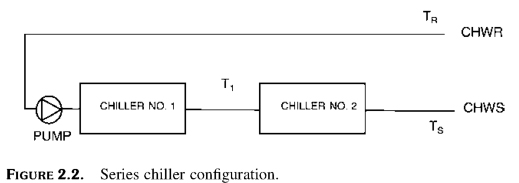

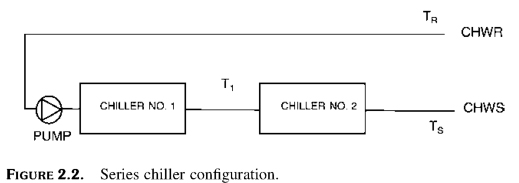

When desirable to have multiple chillers, there are two basic configurations that can be used sequentially or in parallel. In a series of configuration with two chillers, as shown in Fig. 2.2, each chiller is selected to produce half of the required cooling at full flow. Thus, half of all spectrum of services on designing is performed each chiller. Load ratios other than 50/50 possible, but it is the most common illness because management tasks coolers with very small temperature differences.

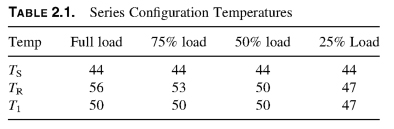

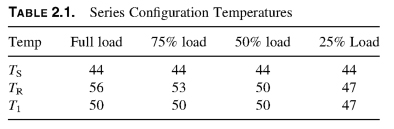

Table 2.1 shows the temperatures under various load conditions for the configuration shown in Fig. 2.2.

A series of cooling are rarely any longer, because this configuration requires a constant flow of cooling liquid at all times, because of the high pumping costs. But, if a relatively large temperature difference required or if there is a very stable base of cooling load, configuration series offers several advantages.

In parallel hmm configuration is much more common. In two-hmm configuration, each chiller, usually selected to work with the same design range, but only half of the total flow in the system requirement. This again results in a 50/50 split load, but with other load ratios can be selected if dictated by operational requirements...

|