|

|

Contact freezing

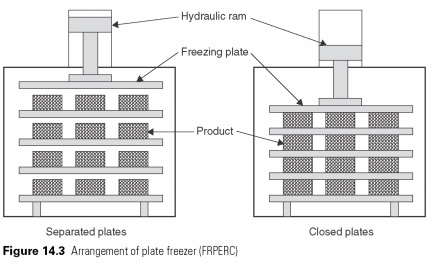

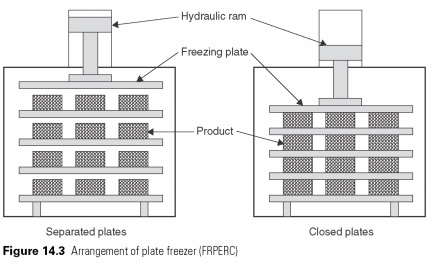

Modern plate cooling system do not differ in principle from the first contact freezer, patented in 1929 Clarence Birdseye. The products in the correct form of packages, such as ice cream, a flat box, pressed between horizontal, flat, refrigerating plates (see Fig. 14.3). It can be opened in addition to the slightly to recognize product and then closed with the help of hydraulic cylinders, to give close the thermal contact. When you freeze a complete plate open again to remove packages. Horizontal plate freezer is shown in Fig. 7.14(a). Vertical plate freezer (Fig. 7.14(b)), is used for bulk products, such as wet fish that is Packed into the cracks between the boards. When the freezing completion of the product is removed in the form of a solid block and can be 75 mm or 100 mm thick.

Contact freezers are less expensive to operate because they are not used fans for air movement. Cooling is done by direct contact of the product with the surface, which, in turn, is in direct contact with the refrigerant or secondary coolant.

The material is frozen, can be fully immersed in cold liquid, such as brine.

It is only suitable for wrapped product. Sodium chloride, glycol and brines not cold enough to get a complete freeze, so this may be the first pre-cooling stage before the final blast. In addition, the liquid nitrogen (196C) or carbon dioxide (78.5C) can be sprayed on the surface...

|