PLACEMENT AND INSTALLATION OF THE CHILLER

Air-cooled water chiller must be outdoors, to use the air as a heat sink. The location and installation of the air-cooled chiller should consider the following points:

1. Prevent recirculation of exhaust air by placing chiller with large enough to adjacent buildings, trees and shrubs, and other equipment to enable the smooth flow of air to the condenser section. Discharge clearly warmer than the surrounding air, and, if allowed to recycling and type condenser, chiller capacity decreases.

Screening, either by planting the screen or wall should be at least 10 metres from the chiller not be higher than the top of the cooling unit, and have at least 50% of the open square.

2. Community noise must be addressed. And, on the roof applications, vibration, should be taken into account. Cm. Section 6.1 for a detailed discussion of these themes.

3. Access service should be considered. Land areas are preferred roof just because access easier. (Replacement of the compressor on the roof of the chiller can be complex, costly and aggravating due to the need to lift heavy compressor roof level.)

Water-cooled chillers are located indoors and mechanical equipment room or cool your room.

Hmm rooms must be separate from the boiler and require space for the unit(s), chilled water pump(s), condenser water pump(s), and condenser water treatment system (see Chap. 13). ASHRAE Standard 15 adopted by the majority of the building supervision authorities, classifies hmm maintenance, as maintenance of refrigeration equipment, if the amount of refrigerant in the largest hmm exceeds certain levels. If they have been classified in a way, this room should be built to higher standards, including specialized ventilation systems and a detailed analysis of the code for these spaces is critical.

Chillers are large, heavy and noisy, and all of these conditions must be taken into account when searching and determining the size of the chiller number:

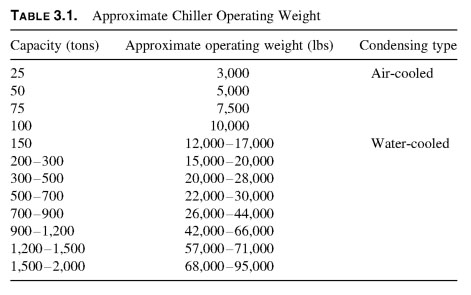

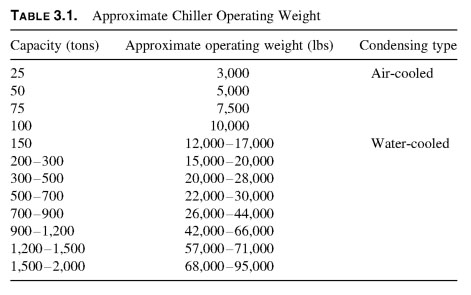

- Table 3.1 lists the operating weights for typical water-cooled rotary compressor chillers. Obviously, it is usually easier to deal with these concentrated scales in a basement or a basement place than the upper floors of the building.

- Noise levels 80-90 dBA can be produced by a chiller at partial load and maintenance of the unit must be designed to contain noise. While the vibration with the help of rotary compressor refrigerating machine is very low, it must also be considered. Again, see Section 6.1 for a more detailed discussion on these topics.

- Refrigerators, pumps, water treatment equipment and others in the chiller room shall be located and constructed to ensure adequate access for maintenance.

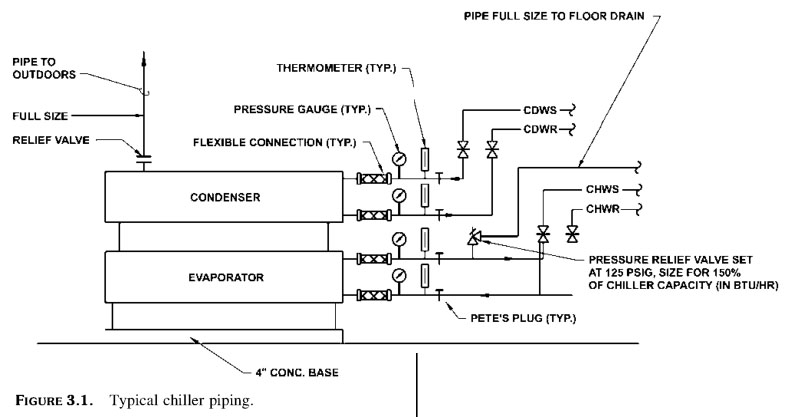

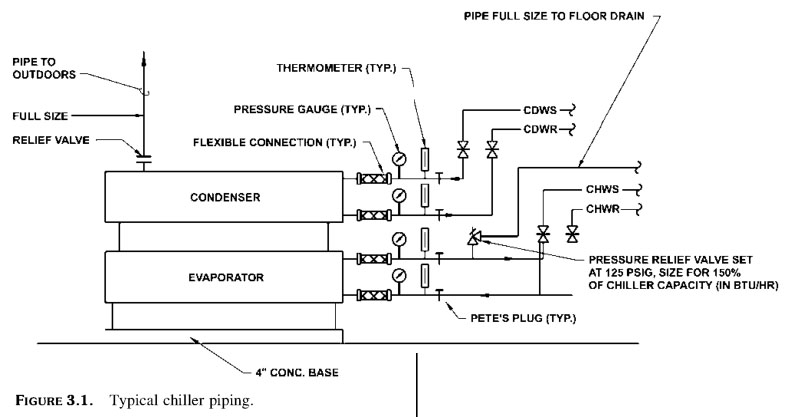

In figure 3.1, pipelines and the installation requirements for a typical chiller compressor installed at or below ground level.

.. ..

|

..

..