Silencer

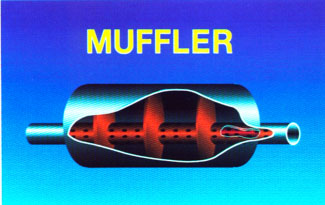

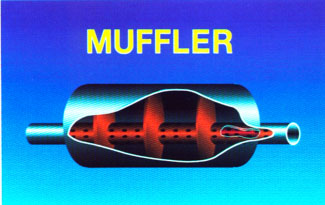

Muffler eliminates or reduces ripple hot gas, leaving the compressor discharge. As shown here, the inner baffle design ripple allows you to get the silencer itself. Each pulse pressure forces the hot gases through the holes in the pipe that runs through the muffler. These pulses enter the chamber, where they are turned off. Internal baffle design will vary depending on the scale and frequency pulse compressor produces. It is designed to prevent the capture of the compressor oil.

Reciprocating compressors are, by their nature, tend to produce the most severe ripple of gas. Rotary compressors produce less ripple, but may still require scarves. Screw and scroll compressors, generate even less gas pulsation; their operation approaches smooth current. They seldom need silencers. Centrifugal compressor has a ripple. It produces a continuous flow of the injected gas, and therefore do not need a silencer. Silencers are installed in the plant on the packaged and split systems equipment as needed.

When the components are purchased separately), careful consideration of the silencer is required.

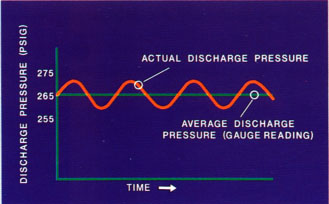

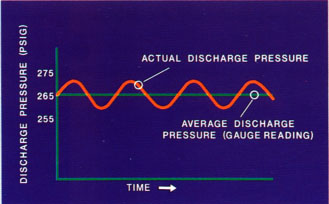

This graph illustrates the fluctuations of pressure in the flue gases in reciprocating compressors. The smooth line represents the pressure you read on the room sensor set. The wavy line is the actual discharge pressure. In one-cylinder piston compressor running at 3600 rpm, the piston compresses the gas 60 times a second. This is the same frequency 60-cycle AC electricity that we use for the work with electric light. Just as the light of the lamp pulses faster than the eye can see, the pressure at the compressor discharge also pulsating at that rate.

In the same way that the eye does not see electrical pulse, your service sensor not able to "see" gas pulse. Sensor told you a constant discharge pressure, when actually it is a very fast moving up and down. This is also true for the suction pressure. The sensor reads the medium pressure. The fluctuations can be from 8 to 12 pounds per squareinch above and below the average pressure in the discharge line.

Some pulsation of piston compressor can be calculated by changing its internal design by increasing the number of cylinders. Almost all reciprocating compressors, however, pulsating enough to justify the muffler. Silencer installed in the discharge (hot gas line as close as possible to the source of the gas pulsation compressoras possible. The goal is to weaken or eliminate the ripple of gas before they are passed through the system. In welded hermetic compressors, muffler often built into the compressor.

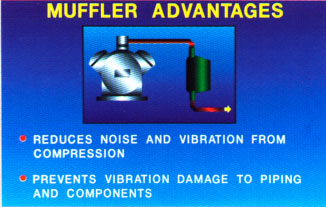

Muffler prevents the hot gas pulsation, that occur in the compressor from carrying noise and vibration through the system and the objects it affects. Noise and vibration that has not dampened may actually increase after leaving the compressor. Noise can become quite annoying people. More importantly, the system components and pipelines can be damaged by prolonged vibration.

Where mufflers are selected and installed in the field, proper engineering practices. Error in the choice may worsen noise and vibration problem. Correct installation is required to ensure maximum effect and prevent oil from getting trapped in the silencer. Silencers should be mounted in a horizontal or downstream part of the hot gas line, immediately after the outlet of the compressor. They should not be installed in the riser pipe...

|