Shell-and-tube condensers

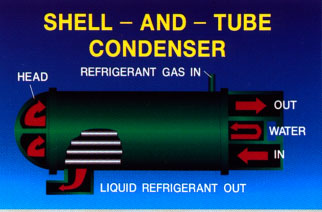

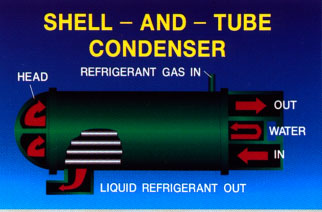

Shell-and-tube condensers are the largest power version with a water-cooled condensers with a capacity from 10 up to 10 000 tons. They work on the same principle of " Shell-and-Coils, capacitors; i.e., with water flowing inside the pipes refrigerant flows outside the tube. You could tell these types that the water on the side of the tube condensers, while the refrigerant in the shell side.

Water makes several passes through the condenser, flows along down and back as many times as capacitor design approvals. The ends of the condenser with water manifolds, urged the leaders who lead the water to anywhere from three to eight passes, depending on the size of the capacitor and the closure is used. These leaders can be unbolted and removed to allow removal of the sediment water from the tube side of the condenser. This is important because fouling caused by water reduces the efficiency and performance of the system. Two other types of water-cooled condensers, tube-in-Tube and shell and Coil must be purged, because they are chemically cannot be disassembled for cleaning.

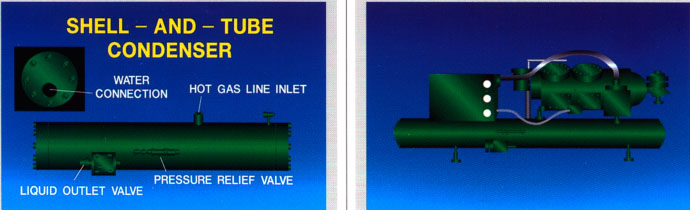

Here you can see how the heads are fastened to the chassis.

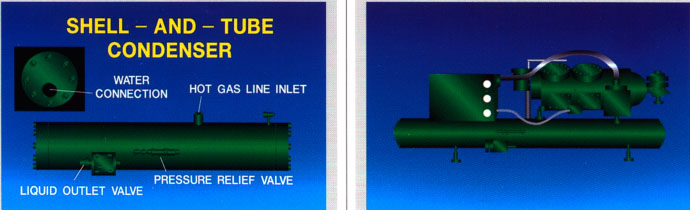

You can also see on the left, one condenser water connection in the lower part of the head. Great mix at the top of the case is a hot gas inlet connection from the compressor discharge. Large valve in the bottom of the hull is the exhaust valve liquid line, where the liquid line will be connected. A small valve slightly above is a safety valve, which is required for safety.

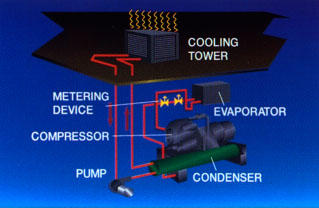

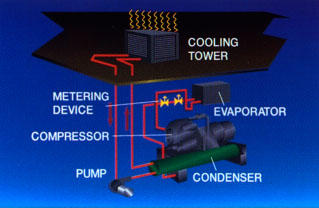

Shell-and-tube condensers can be purchased separately to be used in a system, as shown here. As in the case of air-cooled condenser, this type of use is the exception rather than the rule. It is much more likely to find it in combination with compressor and the necessary piping, wiring, and form controls, factory-assembled, water cooled condensing unit, as shown here. They are used for commercial jobs from 5 to 150 tons of cooling capacity.

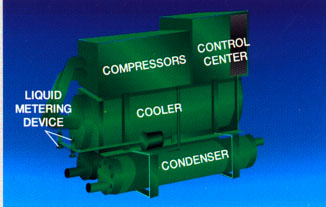

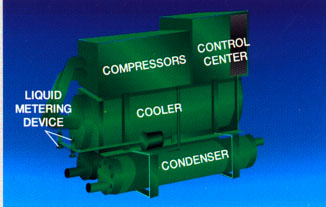

The most common use for a shell-and-tube condensers on packaged piston liquid coolers, for example, the 50-ton model. This is a complete cooling system, with the capacitors at the bottom of the cooler (which cools the liquid used for cooling) in the middle, compressors and control from above. How these components are located on the machine will be different depending on the manufacturer and the power of the machine. On this model, compressors, closed the lid...

|