Capacitors

The capacitor must take superheated steam from the compressor, to cool it to its dew point, and then condense it. This action is opposite to the evaporator. As a rule, two types of capacitors usedair cooled and water cooled.

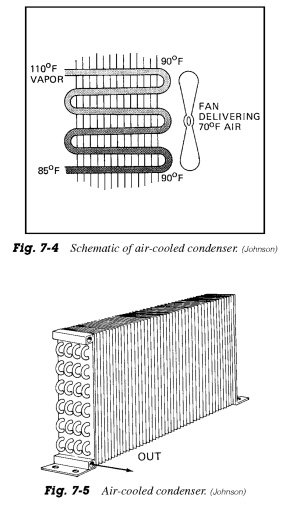

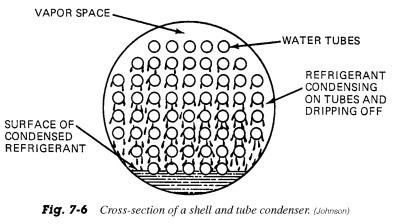

Air-Cooled Condensers

Air-cooled condensers are usually fin and tube type, with refrigerant inside the pipes and air flowing in direct contact outside. As a rule, fan forces air through the coil. This increases its cooling capabilities. Cm. Fig. 7-4 7-5 I.

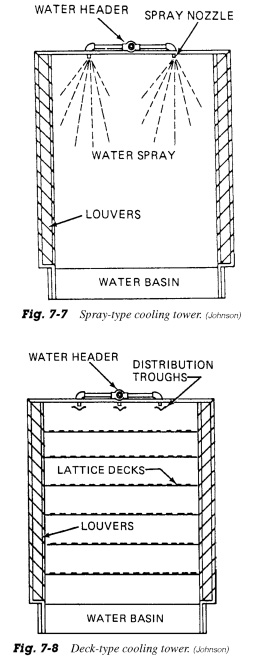

Water-Cooled Condensers

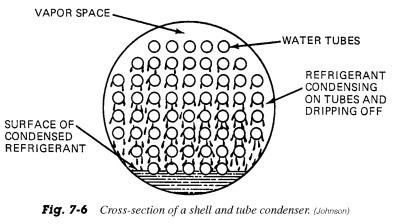

The water-cooled condenser, the refrigerant is cooled water inside the pipe. Cm. Fig. 7-6. Tube containing water is placed inside the pipe or casing containing a warm refrigerant. The heat passes from the refrigerant through a system of pipes for water. Water-cooled condensers are more efficient than air-cooled condensers. However, they must be equipped with plenty of water. The water should be either discharged or to be reimbursed by cooling to a temperature that makes it reusable.

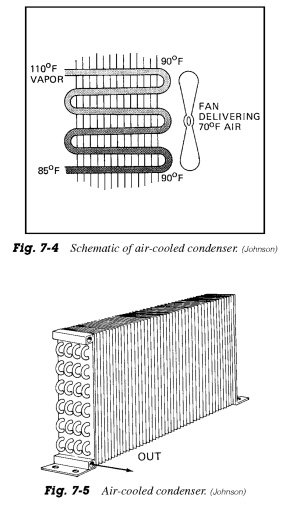

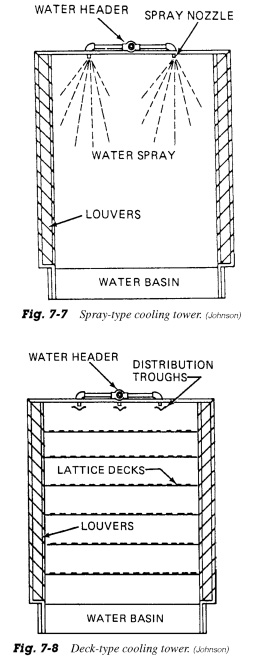

The tower is usually performs reclamation.

Cm. Fig. 7-7 7-8. Tower chills water by spraying in a closed chamber. Air is forced through a spray. Cooling towers can be equipped with a fan to force air over the water spray.

Other device used for cooling refrigerant is evaporative condenser. Cm. Fig. 7-9. Here, gas-filled capacitors placed in a protective housing. Water is sprayed on it, and air forced cooling condenser by evaporation...

|