Spiral compressors

Although scrolling mechanism has been known for many years, patented in France in 1905, it was not until the second half of the last century that it first appeared in commercially available compressors. Production technology is already developed sufficiently to enable the accuracy of the spiral form, you must make it economically.

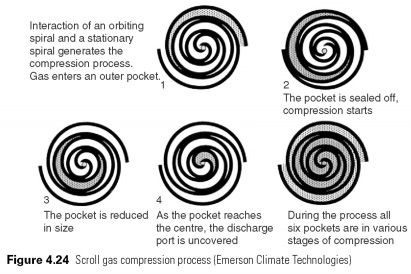

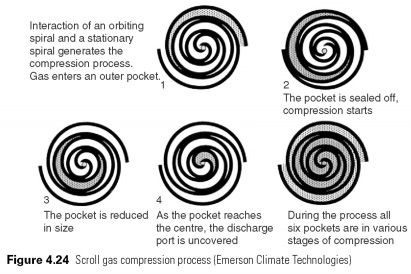

Spiral compressors, reciprocating engines refrigerants, compressed with two connecting pipes, spiral scroll members, as shown in Fig. 4.24. One scroll remains fixed, while the second scrollbar moves in its orbit within it. Please note that if you move the scroll bar is not rotate but orbits with a circular motion. As a rule, in two-three orbits, or crankshaft necessary for the completion of the cycle of compression.

The scroll has some common features with the screw. Both types have built-in volume and so scroll exhibits, I.E. curves, similar in form to those of the screw (Fig. 4.18). There is no clearance volume and therefore, no re-expansion loss.

However, there is a very important distinction compression seal pockets. Screw on the basis of the gap between the rotors and the housing and scroll can be built with contacting seals, i.e. scrolls touch each other in the pocket of the border. This is probably due to the orbital motion generates much lower than the rate of rotational motion, as well as the load on the flanks and tips scrolls can be managed. In addition, there is a direct path between the discharge of territory of the port in the centre of the scrolls and the suction. As a result of very low leakage and heat transfer losses, giving better FIVE characteristics than most other types (Fig. 4.16). This allows you to scroll to operate effectively in a much smaller volume than the screw (Fig. 4.2), with the upper size limit effectively determined by a productive economy.

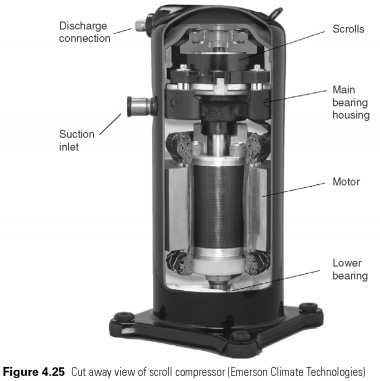

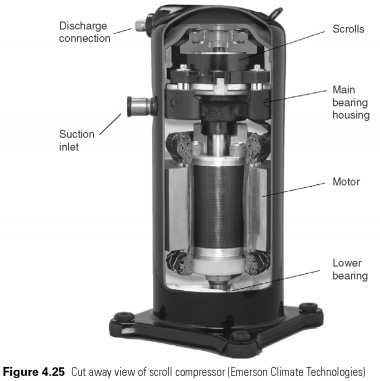

Almost all production scrolls sealed type and typical configuration is shown in Fig. 4.25 . These compressors have the advantages compared with similar sized piston in sealants air conditioning, and this has stimulated investment in capacity, building millions of people worldwide.

Plane bulk curve allows scroll to provide the best cooling, heating and power in the extreme conditions of the compression process smoother and quieter, and far fewer moving parts, guaranteeing very high reliability. In addition scroll has excellent resistance to failures, such as liquid floodback, and compliance mechanisms can deliver unloaded start and extreme pressure protection (Elson et al., 1991).

During the oil injection in the process of compression is necessary, thrust bearing and grease surface is vital. Oil can be used for the upper drive bearings and other surfaces by means of centrifugal forces generated by the offset drilling along the length of the shaft. The ability to control using variable speed inverter several scrolls. Recently a method using intermittent and frequent scroll separation was introduced (Hundy, 2002) . When the scrolls, separated by axially potential is equal to zero. Motor continues to operate at a normal speed, but with very low power consumption and reverse gas flow on the high pressure side, prevents the safety valve. When the scrolls are brought together a normal pumping resumed. The axial displacement of the main scrollbar is driven hydraulically driven piston, in response to a pulse width modulated signal from the controller. Total cycle time is usually 20 seconds, and the duration of the active period, during this time cycle is adjustable. Because the cycle time is relatively short, the thermal inertia of the system has the effect of damping of vibrations, so that the effect is very similar to continuous operation at reduced power.

'Take-off', air conditioning scrolls inspired him to create many options, the most important of which is the refrigeration and low temperature version. As with the screws, use a smaller port of discharge of the compressor to optimize high pressure factors are applicable to lower temperature applications. By introducing the unloading valve, similar to those used in reciprocating compressors, effects when squeezed can be minimized. Liquid injection is used for the cooling where it is needed and economizer cycle can be used to increase the capacity and effectiveness (see Chapter 3). These events allowed the refrigeration scroll to compete with piston types in various commercial applications.

The upper size limit for a single air conditioning scroll through the list was expanded with the introduction of dual scroll which has scroll to the set installed at each end of the horizontal shaft (Pirenne, 2007). About 50% power reduction is achieved idling one of the scroll sets.....

|