Enclosed motors

The majority of compressors available today : enclosed engine and this prevents any possible small refrigerant leakage through the open drive shaft gland. The widespread use of small refrigeration systems led to the evolution of methods of avoiding condensation of a shaft, provided that the working fluid is compatible with the materials, electric motors and has a high dielectric strength.

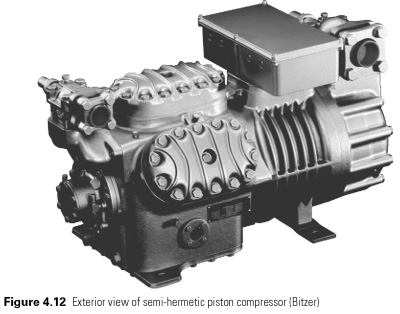

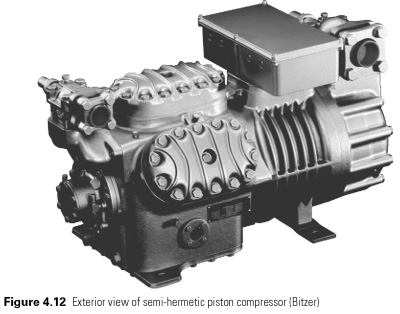

In the semi-hermetic or unavailable-hermetic compressor (Fig. 4.12) its rotor drive the engine of an integral with extended crankshaft, and sta-tor installed inside the expansion of the crankcase. Suction gas passes through the windings of the motor to remove waste heat, but some of the smallest cars, where forced cooling air or the water jacket is used. All switches must be from the crankcase, because any sparking will lead to the decomposition of the refrigerant. Electrical wires pass through a ceramic or glass seals. - Semi-hermetic compressors are built in a very wide range of sizes for industrial and commercial markets. Motor indicated suit compressor and, as such, may be designed for optimum performance in full.

Efficient cooling refrigerant has the advantage that the engine can be more compact than the isolated electric motor.

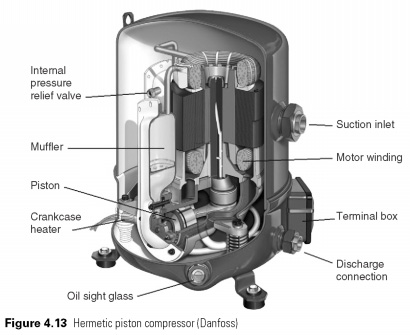

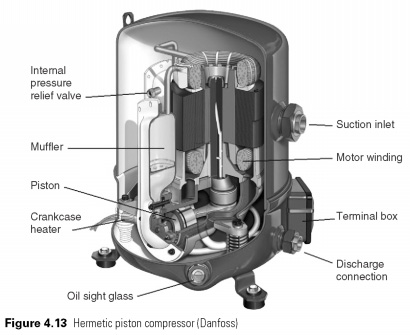

Small compressors can be completely sealed, that is, having the engine and all working parts are sealed inside a steel shell (Fig. 4.13), and, therefore, not available for repair or maintenance. 'White goods ' in the form of household refrigerators and freezers accounts for many millions of hermetic compressors and the concept can be applied in sizes up to tens of kW. They are usually lighter and more compact than the semi-hermetic type and, as a rule, are the two poles synchronous motor speed (2900 rpm, 50 Hz (supply), while the semi-sealants, often four-terminal velocity (1450 rpm). Below about 5 kW power input single-phase motors are used in areas where three phase supplies are not available. Upper limit to the size hermetic compressor determines the expediency of manufacture of welded casing design lends itself to the volume of production methods.

The failure of the built-in motor, is likely to lead to products of decomposition and serious pollution of the system, which then must be thoroughly cleaned. Internal and external motor protection devices are installed with the object of turning off the power before such damage occurs.

Electronic engine power and speed controls provide the means to vary the speed synchronous motors through the generation of electric signals of controlled frequencies. These devices are usually called inverters and they can be very useful, especially in close temperature control applications where the stop/start or step-change in the power lead to undesirable fluctuations. Some for speeding may be possible if a suitable motor. You have to ensure that the compressor motor and the compressor suitable for the inverter. There will probably be a minimum speed limit, due to the lubrication requirements. Inverters have an internal electrical losses, but also because the signal on the engine deviates from a pure signal, additional losses in the engine and overheating can occur.

DC motors are now used in some small compressors and require a Converter for conversion of AC. The advantage of this approach is that only one motor is required for each model, regardless of supply voltage. The traditional synchronous AC motor together with its system of protection developed in different versions for different voltages and frequencies, existing in different countries. This results in a single model of the compressor having a number of parameters that must be made for the future. The DC motor is universal and provides an additional variable speed capabilities.

Need a very small compressors driven by low voltage DC power supplies. Typical examples are the batteries in small boats and mobile homes, where they do not have a voltage generator. It is also possible for receipt of such a proposal from the Bank of solar cells. This requirement was fulfilled in the past, diaphragm compressors driven from the crankshaft and stem from a DC motor, or by vibrating solenoids. The device can obtain the voltage AC compressor low-voltage DC power.....

|