Ribbed-Tube Evaporator

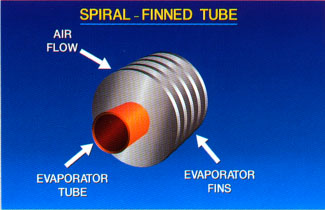

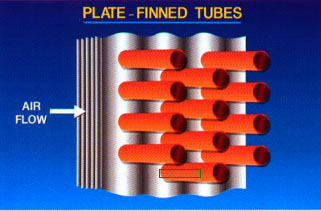

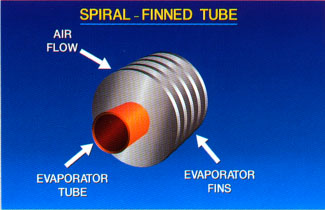

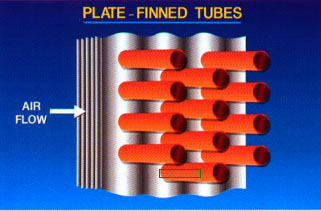

The ribbed-tube evaporator is a bare-tube evaporator, which has a thin metal plate firmly secured to its pipes. The fins can be spirally wound on the tube, as shown here, or they can be rectangular, as shown in the following diagram. The first type are called " spiral finned and the second is called ribbed slabs. Fins serve to increase the efficiency of heat exchange coil, and the effect of increasing the coil of the total area. Finned-tube coils can, therefore, be more compact than the bare coils without sacrificing power. Prime the surface of the evaporator contains a large space. Liquid cooled passes through these premises, untouched by the coil. The ribbed-tube evaporator, on the other hand, uses its fins to reach into a vacant space between the coil pipes and conduct heat back to the tube(s)to which it is attached.

The material of the plates must be a good conductor of heat, such as aluminum or copper, and it must be firmly fixed coil pipes.

The distance between the fins varies from 1 to 14 fins per inch. The lower the temperature of the heat exchanger, the farther apart, as a rule, fins. Air conditioning coils range from about 8 to 14 fins per inch, while a cooling coil use from 1 to 3 fins per inch, because frost easily blocks the flow of air through the heat exchanger when the fins are located close to each other. Natural draught (convection) evaporators use wider spacing than forced draught types, so that the resistance to air flow is minimised.

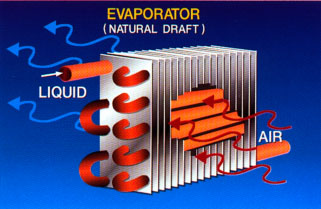

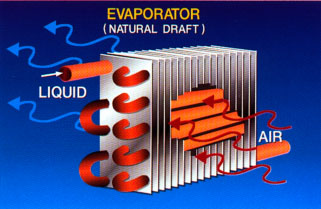

Here is a natural draught, ribbed-tube evaporator. Because cold air is denser than warm air, he falls without the help of a blower. Warm air rises up to take his place. Thus, this type of coil is mounted vertically on a high wall, or horizontally just below the ceiling space, it cools. Since the flow of air through natural draught, coils easily interfered with, the fins are far from each other and the number of coil line, as a rule, is limited to three or less. Three rows of pipes of the coil shown here. Evaporators are set such that they cover most of the length of the space cooling. This type of evaporator is typically used in refrigerated display cases, florist boxes, and so on.

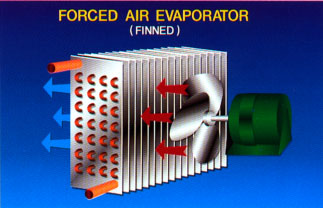

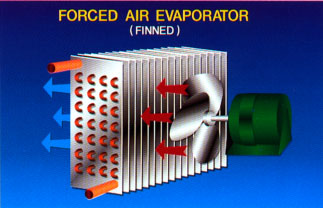

Once the coil capacity increased by adding fins to its tubes, so is its capacity increased by forcing air above it. Both methods permit a greater amount of heat to be absorbed in the leg evaporating pipes, achieving naked evaporator tubes. The end result is a more compact coil with the same cooling capacity. As a rule, the reduction in size reduces costs. Thus, it made evaporator gives more cooling for the dollar than the battery tube, natural draft of the evaporator or the bare-tube evaporator.

As the construction and equipment of space is always at a premium, and the frost is not accumulate on the evaporator, forced air evaporator is used in the vast majority of air-conditioning systems. This is true for both residential and commercial markets. Products designed for free air discharge in space, as a rule, use a propeller fan, as shown here, and those connected to a duct system use centrifugal fans. Forced draft, finned-tube evaporators almost always use the D-X delivery of the refrigerant, because their primary application with refrigerants used in air conditioning...

|