Refrigerating Systems. Superheating and subcooling

Overheating (referring to the overheating of refrigerant vapour at the outlet of the evaporator) and hypothermia (referring to the refrigerant sub-cooling liquid leaving the condenser) are, apparently, two important processes in practical steam-compression refrigeration system and are used to ensure maximum performance (COP) and to avoid some technical problems, as will be described below.

Overheating In the process of evaporation of the coolant is completely vaporized be obtained through the evaporator. Cold refrigerant vapor continues through the evaporator, heat is absorbed for a steam heat. Under certain conditions such pressure losses due to friction increase the volume of overheating.

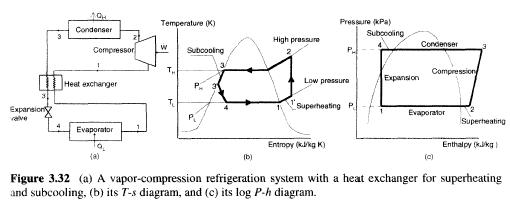

If overheating occurs in the evaporator, the enthalpy of the refrigerant raised, removing the additional heat and increasing the effect of cooling evaporator. If it is provided in the compressor suction, no useful cooling occurs. In some systems, the cooling liquid-vapor heat exchangers can be used to overheating of the saturated vapour refrigerant from the evaporator refrigerant liquid coming from capacitor (Fig. 3.32). As can be seen from Fig. 3.32, the heat exchanger can provide high system COP. Overheating of the refrigerant can be obtained in the compressor. In this case, saturated vapour refrigerant enters the compressor, and overheated, increasing the pressure, leading to an increase in temperature. Overheating received from the compression process does not improve the efficiency of the cycle, but great results condensation equipment and a large compressor, the supply pipe. The increase in the refrigeration effect, obtained by superheat at the evaporator, as a rule, offset by a decrease in the cooling effect in the compressor. Because of the volume flow compressor is constant, the mass flow rate and the refrigerating effect decreases decreases the refrigerant density caused by overheating. In practice, it is well known that there are losses in the cooling capacity 1% for every 2.5C overheating suction line. The isolation of the suction line is the decision, to minimize heat gain. Cooling is the process of removing excess heat from the superheated refrigerant vapor, and if achieved using an external effect, he will be more useful for the COP. Cooling is often considered inappropriate, due to the low temperature (less than 10 C) and a small number of the available energy.

Hypothermia This process of cooling liquid refrigerant below the temperature of condensation in the pressure (Fig. 3.32). Hypothermia provides 100% of the liquid refrigerant to enter the expansion device, preventing bubbles of steam from hindering the refrigerant flow through the expansion valve. If hypothermia is caused by the method of heat transfer for external cooling cycle, refrigerant effect of the system is increased, because the supercooled liquid less enthalpy than saturated liquid. Hypothermia is carried out by cooling the liquid line system, using a higher temperature. Simply, we can say hypothermia is chilled by the refrigerant and more provides the following respectively: Increase the energy load,

Reduction of electricity consumption,

Reduction pulldown time,

More uniform temperature refrigeration and

Reduction in the original cost. Note that the performance of simple steam-compression refrigeration system can be greatly improved by further cooling liquid refrigerant, leaving the condenser coil. This is the subcooling of liquid refrigerant can be accomplished by adding mechanicalsubcooling cycle in normal pairs compression cycle. Hypothermia system can be either a dedicated mechanical-subcooling system or integrated mechanical-subcooling system (Khan and Zubair, 2000). In a dedicated mechanical-subcooling system, there are two condensers, one for each of the main loop and subcooler cycle, while for complex mechanical-subcooling system, there is only one capacitor, serving as the main loop and subcooler cycle. For example, hypothermia R-22 13C increases the effect of cooling by about 11%. If hypothermia received from outside the loop, each degree increase hypothermia will allow to increase the throughput capacity of the system (approximately 1%). Hypothermia inside the loop, can not be effective, because it compensates for the effects in other parts of the cycle. Mechanical hypothermia can be added to existing systems developed in the new. It is the ideal place for any refrigeration process in which more opportunities, that may be necessary or operational costs must be reduced. It proved to be cost-effective in a variety of applications and is recommended for large supermarkets, warehouses, factories and other Fig. 3.33 shows a typical subcooler for commercial refrigeration equipment.

..

|