All-Air Systems

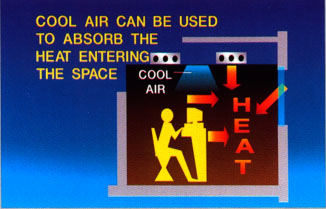

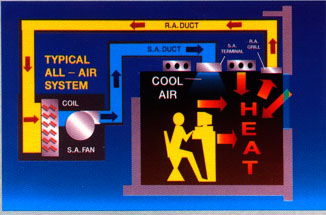

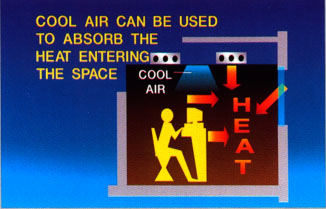

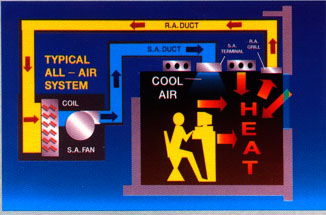

With the purpose of cooling zones, the air, the system provides a cool, dry air. After the air enters the space, it absorbs heat and moisture. The temperature of space, as a rule, is at about 75F) and a relative humidity of 50%. Cool the air in space, usually from 50 and 55F.

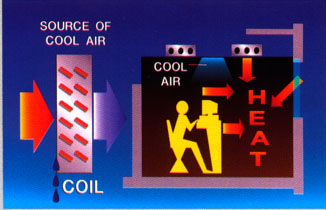

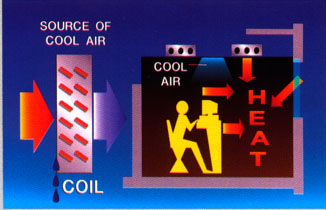

This fresh air is cooled and dried when passing through the coil surface temperature is cooler than the air. The heat from the air flows through the metal plate and tube heat exchanger in the refrigerant circulating through the coil. Moisture is removed from the air as it condenses out of steam in the cold liquid on the surface of the coil. This is the same thing that happens when a glass of cold drink "sweats." The condensed moisture is transferred from the surface of the heat exchanger for drainage of waste.

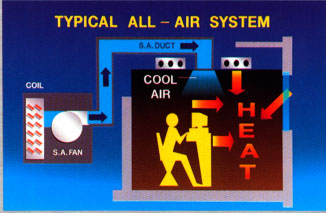

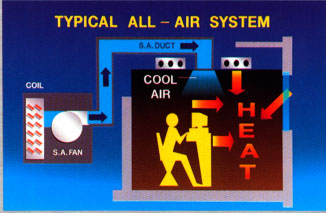

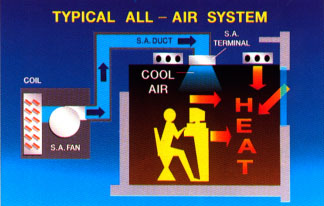

Cold, dry air supply leaving the cooling coil is transported from the coil to the conditioned space through the duct system.

Air duct can be made of metal, plastic or fiberglass and isolated to prevent air from warming up before he gets to the place. The energy needed to move the air through a duct ensures the supply air fan.

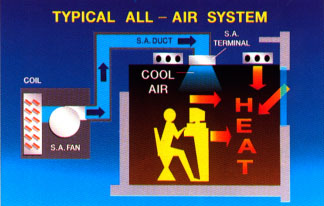

Supply air terminal or diffuser is used for the uniform distribution of cold air into the room. It is the most important determinant of good air traffic services. Bad selection or arrangement of the diffuser(s) causes discomfort. Drafts, dead air spots and dumping of cold air directly at the inhabitants of the symptoms of ill diffuser selection and arrangement. No amount of maintenance work will be to fix a bad design.

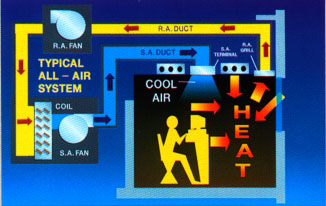

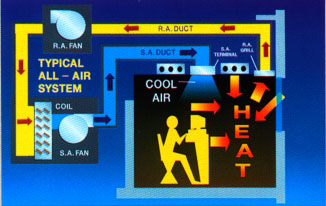

Because the air is pumped into the space by supply air fan exhaust air grille must be ensured in order to remove the warm air from the space. After entering the grille, the return air is drawn back to the coil through a system of ducts. Then it can be cooled, and again returned to the conditioned space.

Some systems include return air fan. This is useful in overcoming resistance to air flow in response duct systems, that for a long time or who have a lot of branches. He is also preferred by some engineers systems, which can be up to 100% outside air into the room. Return air fans, as a rule, are the exception rather than the rule in the systems below 60 tons of cooling capacity. When the recirculated air reaches the coil cooling again and sent back to space. Air conditioning so the cycle repeats.

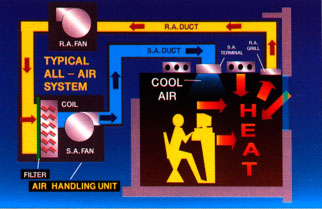

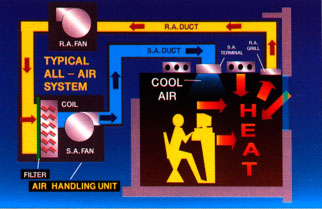

Particles of dirt, dust, and other impurities are removed from the circulating air by installing filters in the system. Filters are available in a variety of types, depending on the type of equipment used and the degree of efficiency of filtering better. A small tank, air purification systems tend to offer less effective filtering and less diversity of filter types, the greater the capacity of models.

Filters, springs and the fresh air blower, as a rule, are combined into a product called the air handling unit, sometimes abbreviated to AED. In sizes below about 20 tons, the Assembly is sometimes called the fan coil unit. We will see later in this module unit in combination with other parts of the system.

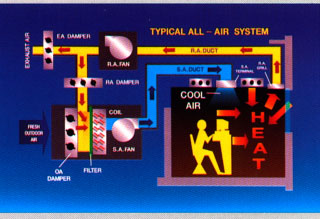

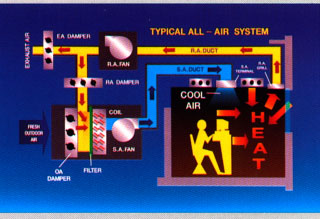

The smell is controlled within the space diluting it with the outside air. The air handler brings outside air into the system, then filters and controlling its temperature when you move it through the coil, before sending it to its place. The outdoor air is mixed with the air returning from space, before you start treatment on a spool. Because outdoor air is delivered into the system, equal to the number of stale, return air must be exhausted from the system. Outdoor, return, and extract air dampers to work together to coordinate the amount of outside air entering the system and exhausted. Remember that the air conditioning system varies, and some housing projects do not offer these options...

|