Types of accounting devices

We have assumed that the refrigerant in the bulb, R-22. For many comfort applications, however, other refrigerant or even another type of chemical used. Such valves say offset valves. Cross charged valves are also used for commercial work, where the constant overheating is not mandatory.

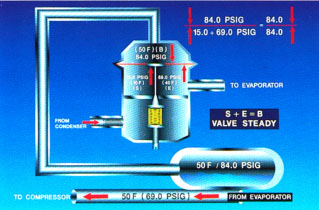

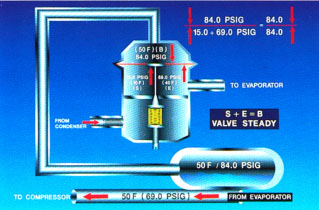

50F saturation temperature in the ball, pressure is about 84.0 pounds per square inch. This is the pressure put on the top of the diaphragm. Below the diaphragm is the spring pressure, 15.0 PSIG, plus the pressure in the evaporator. 40F saturation temperature of the evaporator pressure on 69.0 pounds per square inch. The combination of spring pressure and the pressure in the evaporator below the diaphragm is 15.0 + 69.0 = 84.0 pounds per square inch. This coincides exactly with the pressure above the diaphragm is bent up, down, and the needle remains where it is.

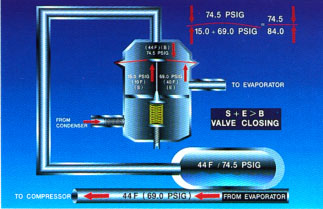

As the cooling load is reduced, but at the same needle position is saved, the refrigerant in the evaporator superheated less.

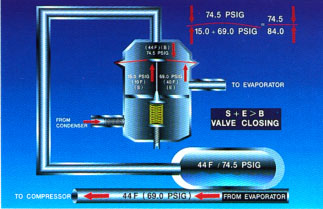

If the super drops heat up to 4actual (hot) gas temperature in the suction line of the sensing bulb will be 44F. the sensing bulb, 44F saturation temperature produces a pressure of about 74.5 psi above the diaphragm. Pressure below the diaphragm still 15.0 psi (spring) + 69.0 psi (evaporator) or 84.0 pounds per square inch. This drop in pressure causes the diaphragm to bend upwards, that the needle is moving towards " closed". This situation will continue until 10F overheating found again in the suction line at the lamp place. When this happens, the pressure above the diaphragm returns to 84.0 pounds per square inch.

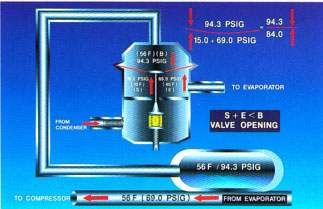

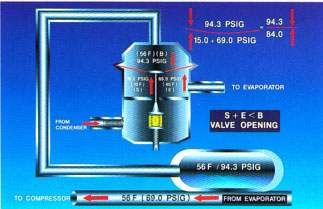

As the cooling load increases, but the needle remains in its equilibrium position, the refrigerant in the evaporator superheated more. If overheating rises to 16F actual (hot) gas temperature in the suction line of the sensing bulb will be 56F. the sensing bulb, 56F saturation temperature yield a pressure of approximately 94.3 pounds per square inch. So, above the diaphragm we have 94.3 pounds per square inch, while below we 84.0 pounds per square inch. In this case, the diaphragm, leans down and the arrow moves towards the open position. Aperture will be bent down to 10F overheating again returned to the suction line of the sensing bulb place. This action returns the pressure above the diaphragm to 84.0 PSIG...

|