Repairing Leaks

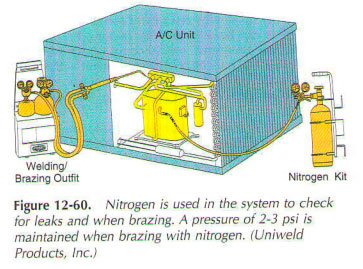

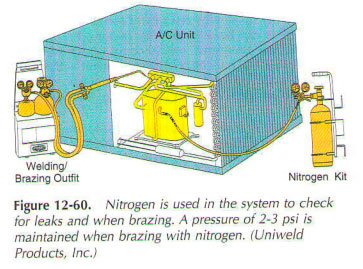

To repair the leak, destruction and recovery of refrigerant from this part of the system. (In some cases, you will have to empty the entire system.) Check the pressure to be sure that it's 0 psi (neither pressure nor the vacuum in the system). If possible, avoid brazing or soldering system with refrigerant. The heat may damage the refrigerant. Method of brazing and soldering of parts of the system implies the use of nitrogen. Nitrogen cylinder attached to the process tube. The system is under pressure and checked for leaks. If the leak is found, the area can be brazed. The system should be reviewed for leaks before the removal of nitrogen cylinder,

Refrigerant systems are made of copper, steel and/or aluminum materials. Leakage may start in any part of the system. Repair depends on the material from which the failure occurred, or the combination of materials for leaks. To find out what kind of metal is used, scratches on the surface. Steel gray-white. It is very magnetic. (Using a magnet for testing.) Copper is a reddish color when scratches and nonmagnetic Aluminum with white, soft and non-magnetic.

Steel and copper can be brazed; aluminium can be aluminium-brazed or soldered. Aluminium can be resistance welding of steel or copper. It can also be repaired using epoxy glue.

Leaks that are most often found on pipelines. If they occur in a flared connection, the following reasons are possible:

- The tube flare is not correct.

- Nut were not tightened properly.

- Thread deleted.

It is better to replace a leaking installation, making new outbreaks. Use the new flared fittings. Leakage in brazed or silver-soldered connections can be restored by cleaning, coating with the flow, and heat. Steel pipes, as a rule, has. along the seam. This seam should be clean for soldering. Clean the wire-brushed along or file off enough metal to remove a seam depression.

If the installation has been dismantled, reflux and assemble. Warm connection and brazing or soldering it in place. Avoid overheating the other parts of the system. Never heat the kiln. The moisture will be driven in the system. It is better to cut the pipe with the help of pliers or a cutter.

Use fire-resistant sheet material as a protective barrier between combustible surfaces and open flame. This type of material is also used when the handset is next to the metal side. Aluminum evaporators can be repaired using epoxy glue. Follow the manufacturer's instructions.

Check for leaks before the unit is evacuated. Moisture can enter the system through leakage during evacuation or pump-down. Always use the correct recycle/ recover when placing equipment and repairing leaks.

When determining the leakage or fault in the cooling system, the technician must restore all of the refrigerant from the device. Most small hermetic systems use R-12 refrigerant. R-12 CFC refrigerant and cannot be vented into the atmosphere. The restoration includes removal of the refrigerant tyres refrigerant from the system and cleaning his car back. The refrigerant can be placed back in the instrument or send refrigerant reclamation center.

After you restore or recover refrigerant, service technician can use a vacuum pump to evacuate the system before recharging.

.. ..

|

..

..