PLATE EVAPORATORS

The plate evaporator version chillers with most rapidly gaining popularity. It is a relic of plate and frame heat exchanger, which was used in the food industry for many decades. Plate and frame heat exchanger consists of a set of plates, which are gasketed so that, when these plates are bolted together one of the liquid flows between two plates, and other liquids between pairs of adjacent plates. Corrugated plates with a herringbone pattern that physically strengthens plates, and also contributes to the turbulence of the fluid, providing excellent convection heat transfer coefficients. This type of heat exchanger is attractive for such branches of food industry, as dairies, because at the end of the working shift bolts of fastening of plates in a position can be relaxed, allowing access to any surface cleaning.

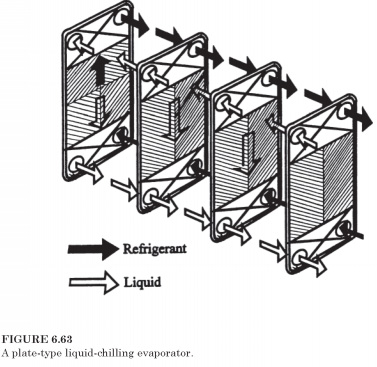

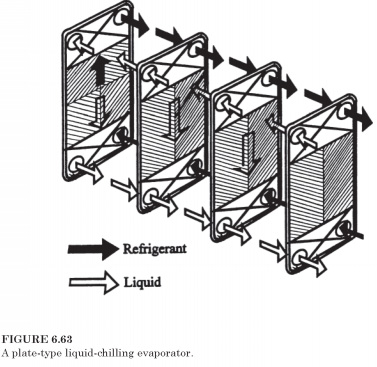

Transform plate and frame heat exchanger heat transfer between two liquids creates a problem, as the seal of the refrigerant passes. This goal is achieved through the construction is shown in Fig.

6.63, where instead of each sheet of separate pairs of plates, forming a refrigerant excerpts brazed or welded. For Halocarbon refrigerants, normal soldering edges enough, but for ammonia or Nickel brazing or welding it is necessary. The liquid flows down between her two boundary of the plate, while the refrigerant flows upwards, so a counter to the liquid. Refrigerant enters the evaporator in the lower right part of the refrigerant flowing up the first pair of refrigerant plate, and the remainder passing subsequent pairs.

At the end of refrigerant vapors left of figure, near the plate shown in parts, to illustrate the refrigerant flows upwards. Each flow of the refrigerant leaves his pair in the upper right, and the connection threads of the other couples, finally, from the evaporator in the upper right corner. Construction is shown in Fig. 6.63 has closed, collapsible passage between one refrigerants and another, so while the edges of the plates are welded, there is a small collapsible joint.

The external boundary of the fluid passages outside refrigerant vapor. Some small plate evaporators for Halocarbon refrigerants made without gaskets for soldering all connections. Evaporators industrial, which is usually more, made by bolting together the vapors. Perhaps, then, to dismantle the evaporator for treatment of liquid side surfaces must they become contaminated. Such dismantling means that the refrigerant passes are also open for air, so the refrigerant must first be evacuated.

Key strengths of the plate-type evaporator are: (1) the high heat transfer coefficients, (2) low level of refrigerant, and (3) small size. These benefits are linked, because whenever the heat transfer coefficient can be improved, the heat exchanger can be less than the specified cold output. Small exchanger automatically leads to lower refrigerant charge. Ranges of General heat-transfer coefficients are reported one source31 2500 up to 4500 W/m2 K (440 up to 790 Btu/hr-ft2-F) water/ammonia and from 1500 to 3000 W/m2 K (265 up to 530 Btu/hr-ft2-F) water/R-22. Another source32 assumes values for flooding or recycling of water/ammonia evaporator to 2840 3975 W/2-K (from 500 to 700 Btu/hr-ft2-F). For direct expansion of ammonia, the overall heat transfer coefficient can be expected in the range 2275 to 3400 W/m2 K (from 400 to 600 Btu/hr-ft2-F).

Three main types of refrigerant feeddirect expansion, filled separator, and forced the liquid overfeedall used with this type of evaporator. Flooded and liquid overfeed usually operate more efficiently, but directexpansion organization is the simplest. Difficulties with direct expansion results in an even flow distribution for each refrigerant passes.

|