Pressure Limiters

Sometimes, the pressure, the limitation of the expansion valve is used to prevent overloading of the condensing unit. Pressure limiters are designed for applications where the evaporator pressure must not exceed the limit of safe work.

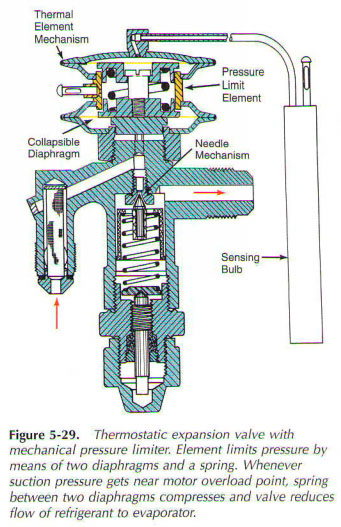

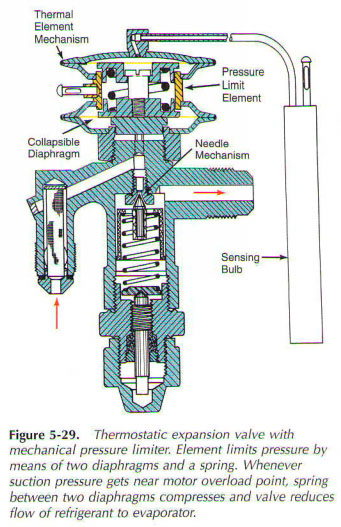

The pressure limiter is placed between a sensor and a needle valve. In the structure of the diaphragm and spring, designed to collapse in a certain force. Thus, if the item is designed to collapse at 40 psi (377 kPa), the needle will close if low pressure is higher than this amount, regardless of the evaporator temperature-pressure. These valves offer fast pulldown on start-up. Cm. Fig. 5-29.

In gas-filled folding element can provide extreme pressure, which will open the valve. When low pressure exceeds a certain value, the diaphragm will collapse. Noncondensable gas and obeys Charles Boyle and Laws.

When the refrigerator warm, pressure limiter prevents a long time at overly low side pressure. An example is shown in Fig. 5-30, cycle show pressure drop of more than 50 pounds per square inch to 10 psi (446 kPa "170 kPa) in just a few minutes.

The device then two hours passed before it shuts down.

Another type of pressure limiting thermostatic expansion valve is shown in Fig. 5-31, This valve has an adjustable pressure limiter. Above a certain value of pressure above the diaphragm spring compresses instead of needle valve opens.

Often, you must have two different levels of the pressure control valve. A control valve with two pilot pressure regulators, called dual-pressure regulator. This system uses a switching mechanism for the selection of high or low pressure, a control.

Maximum working pressure (MOP) or pressure limit can be achieved with the help of specially thermostatic free. SS thermostatic charging is a modification of the usual limited liquid thermostatic free. This allows you to valve bulb temperature and the respective lamp pressure (opening pressure) were achieved. Valve damper or closed. Increase bulb temperature is above a certain value causes little or no increase in pressure light. The SS parameter comparable pressure limit setting of the mechanical pressure limiter.

There are two differences between the SS thermostatic fees and conventional thermostatic charges. The first is that the SS thermostatic valves are closed tightly during out-of-cycle. As vaporizer heats up in out-of-cycle, at the point of maximum pressure light in the cell. The increase in temperature of a flask does not increase the lamp pressure (opening pressure). Thus the evaporator pressure (closing pressure) continues to grow. With the assistance of spring pressure (closing pressure), the valve closes tightly.

The second difference is that the thermostatic expansion valve is closed during the month pull-down. Although temperature and relatively high pressure in the evaporator with a pull-down, the valve remains closed until the boiling point decreases below MOP thermostatic free. This allows you to quickly pulldown, avoiding floodback and overload of the compressor motor.

Thermostatic charges using the maximum working pressure (MP) require from your diaphragm and capillary tube is kept at a temperature warmer than the lamp during the production cycle. This is necessary because the valve will be controlled by the lamp. If the aperture becomes colder, than a lamp, a thermostatic charge can move to the diaphragm case. Control from the lamp will be lost. Valve is closed or the throttle.

Maximum operating pressure thermostatic charges with comfort cooling systems. They are also used with indoor and outdoor coils heat pumps.

.. ..

|

..

..