CL compressors

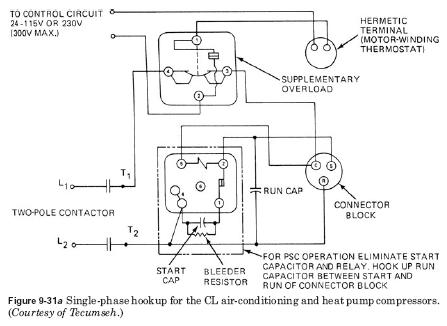

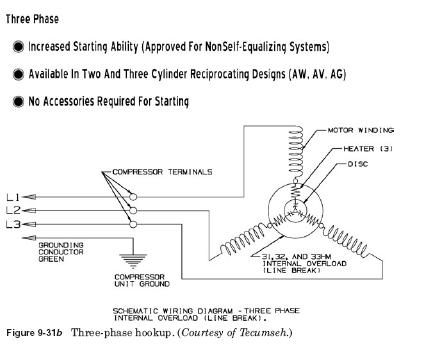

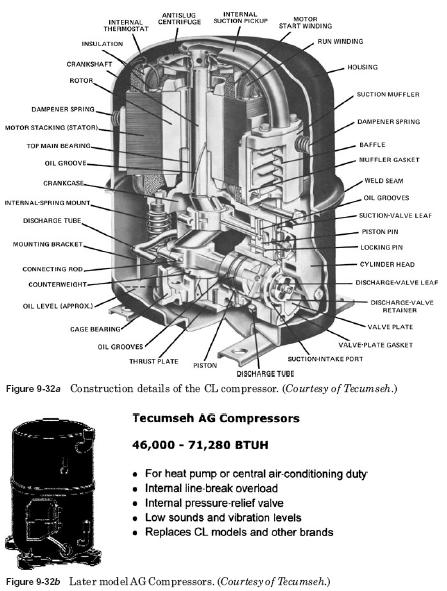

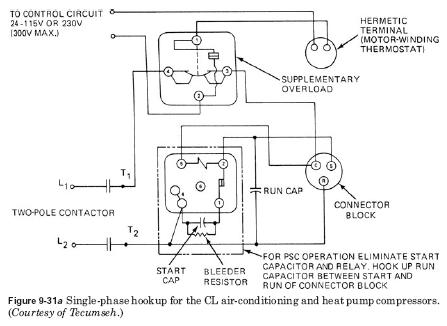

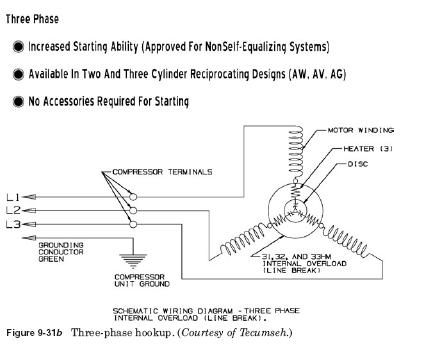

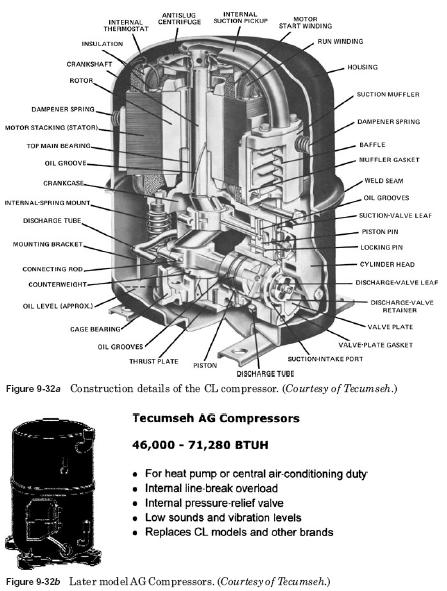

CL compressor series is designed for residential and commercial air conditioning and heat pumps. These compressors are manufactured in 2-1/2, 3, 3-1/2, 4, and 5 liter sizes. They can be operated on a three-phase or single-phase power supply (see Fig. 9-31). Because it is one of the largest compressors it has two cylinder and piston. She needs a good system of protection for the engine. It has an internal thermostat to interrupt the control circuit for motor contactor. Contactor then shuts down the compressor from the power source. Fig. 9-32 shows the location of internal thermostat.

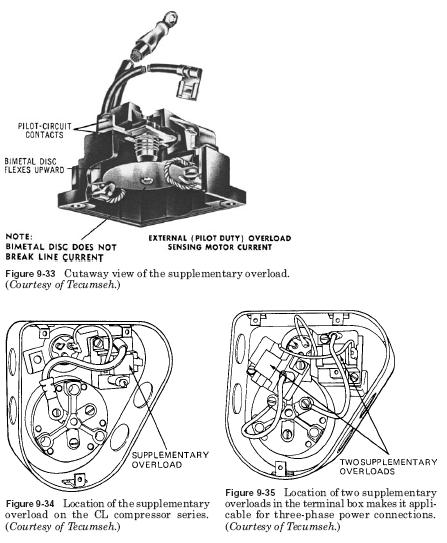

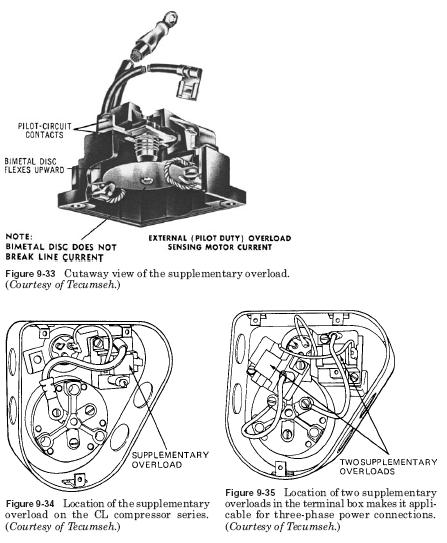

An additional overload of the compressor terminal box, so that this can be achieved room (see Fig.

9-33). Alocked rotor or another able to produce excessive current causes the bimetal disc flex up. This opens the pilot circuit motor contactor.

Contactor then shuts down the compressor from the power source. Single-phase power supply required is one additional overload (see Fig. 9-34). Three-phase power supply requires two additional overloads (see Fig. 9-35). This CL line compressors are used R-22 and R-12 (R-134a) or suitable substitute refrigerants. They also use oil responsibility of either 45 or 55-oz. In some cases, when the blocks are connected with each other, they use 65 oz.

AJ compressors

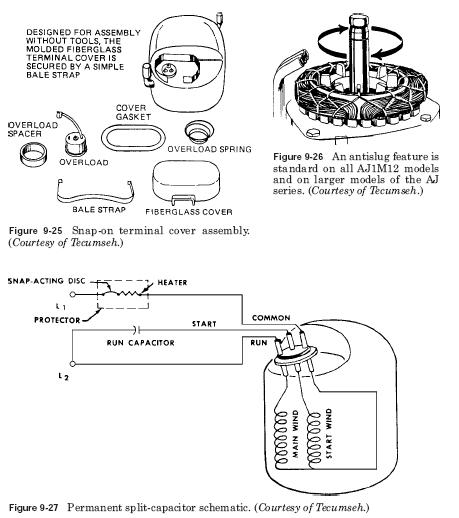

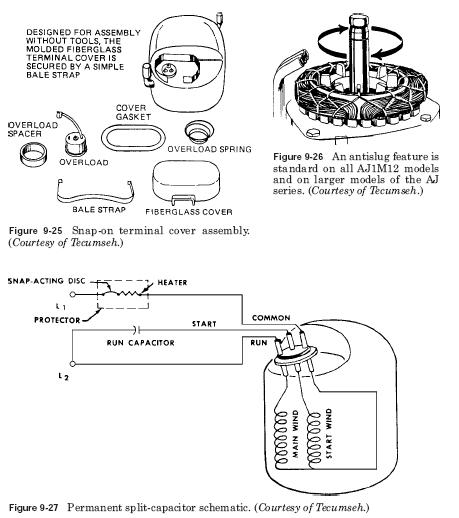

AJ series Air conditioning compressors varies from 1100 to 19,500 Btu (see Fig. 9-23). Oil charge 26 or 30 oz is a standard, depending on the model. They are mounted on three or four points (see Fig. 9-24). Snap-on terminal allows quick access to the connections under the cover plate (see Fig. 9-25). This particular model has antislug function, which is the standard for all AJM 12 and larger models (see Fig. 9 to 26). (Anti-slug function keeps the liquid refrigerant movement.)

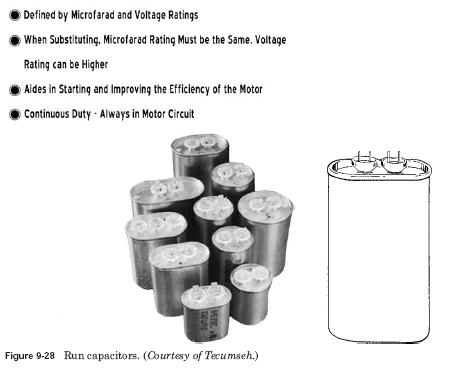

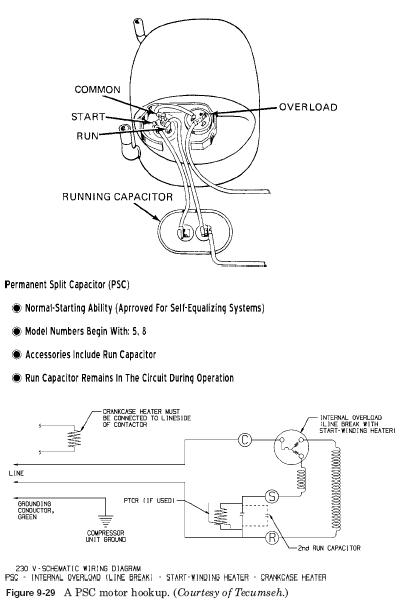

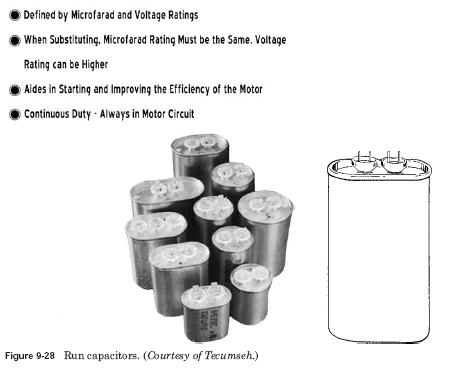

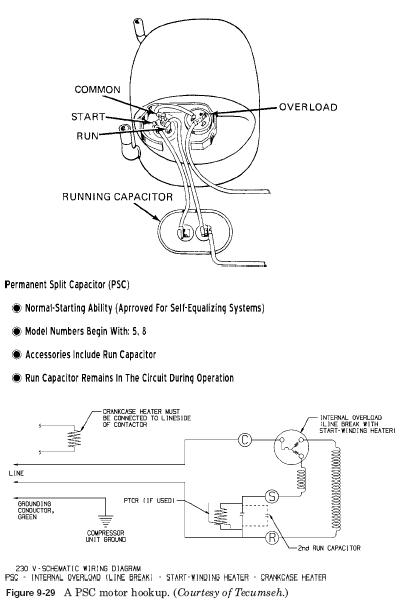

This type of compressor relies on a permanent split capacitor motor. In this case, how to start and run capacitor. Start relay and filter capacitor, are eliminated in such a scheme (see Fig. 9-27). With the PSC motor capacitor, operates and how to start and run capacitor. He never disconnected. As the motor windings are always busy when the compressor starts and runs.

JSC engines provide good running characteristics and sufficient starting torque with low line voltage conditions. They reduce potential engine trouble with the electric circuit is a simplified (see Fig. 9-28).

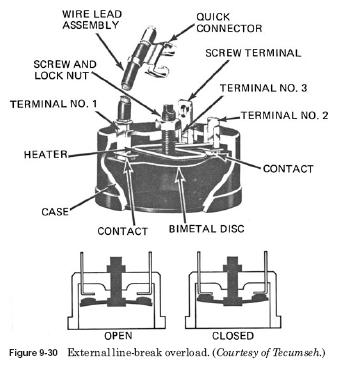

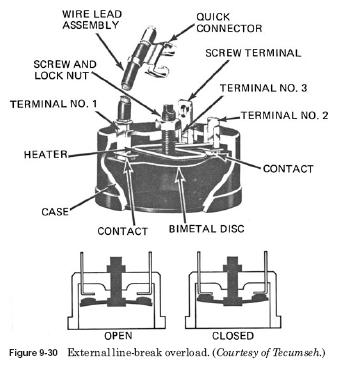

Figure shows the condenser is designed for continuous operation. This increases the efficiency of the engine with an increase in power and reduction of power consumption from line. Do not operate the compressor without room to run capacitor. Otherwise, overload leads to a loss of startup and performance. Adequate motor overload protection does not exist. Arun capacitor in the circuit causes the engine has some peculiarities. Such engines have the best characteristics in the derivation of sudden load. Fig. 9-29 shows how this particular series compressors connected capacitor for use at the start and the beginning of the chain. Note overload external switch the line. This motor overload protection device is securely attached to the compressor housing. He quickly felt any unusual increase in temperature, or excessive current. Bimetal disc reacts or excess temperature or excessive current. He bent down, thus, compressor shut-off of the power supply (see Fig. 9-30).

..

|