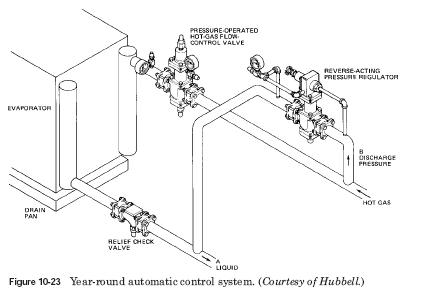

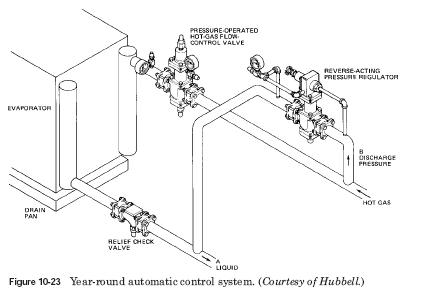

All Year Round-Automatic Constant Pressure Monitoring System Fluid

Permanent liquid control system is a means of increasing the efficiency of the cooling system, which uses air cooling of the atmosphere, or evaporative condensers (see Fig. 10-23). It does this by automatically maintaining constant pressure in the fluid throughout the year to ensure the effective operation. The constant pressure of the liquid at the thermal expansion valves, float, and other devices to expand effective results in the low side of the operation. Hot gas defrosting, liquid recirculation or other refrigerant management systems require constant pressure for successful work. Pressure of a liquid is reduced by cold weather and extremely low wet bulb temperature low cooling load.

To compensate for the reduction measure of the fluid, it is necessary to automatically adjust the discharge to a specified point and flow control pressure relief in the liquid line coming from the condenser, and coming to the receiver.

Thus, the set pressure is applied to the level of the liquid in the tube. Constant fluid control pressure of doing this. In addition, when the compressor starts and stopЂќ pressure is monitored statistics, pressure-operated hot gas flow control valve is tight closing of the valves during shutdown periods. This allows you to effectively start and stopЂќ operation of the compressor to pressure regulation low side. The three valves in the system shown in Fig. 10-23 are

In the reverse action of the pressure regulator

pressure acted hot gas flow control valve

The relief of the non-return valve Functions of the control system is to maintain a constant pressure of the liquid (A). In the back pressure-regulating valve does this, modulation-type valve. It maintains a constant set pressure at the output of the regulator. To maintain a constant pressure (A) it is necessary to maintain the discharge pressure (B) about 5 pounds per square inch above (A). This is achieved by means of hot gas regulator, which will maintain a constant pressure (B) on the upstream or regulator input. Thanks to the structure of the regulator, a constant supply of gas will be available in the specified pressure for supply pressure regulator for reservoir pressure maintenance (A). An excess of hot gas is not required to maintain the filling stream into the condenser. The relief of the check valve prevents pressure (A) causing stagnation in the condenser. When the compressor stops, hot gas flow control valve closes tightly and shuts off the discharge line. This prevents the gas from flowing into the condenser. Check valve actually prevents stagnation of fluid condenser. Thus, the fluid can't back in the condenser, and in very cold weather. Rather low side pressure will be maintained to start refrigeration compressor when required. ..

|