Electronic expansion valves

Electronic expansion valve provides more control and protection system. The advantages can be summarized as follows:

- Precise flow control in a wide range of capacities.

- Quick response to load changes .

- Better control at low superheats so fewer evaporator surface required for overheating. More surface evaporation leads to a high boiling point and greater efficiency.

- The electrical connection between components offers greater flexibility in the layout of the system, which is important for small systems.

- The valve can close when shutting down the system, eliminating the need for additional shut-off solenoid valve.

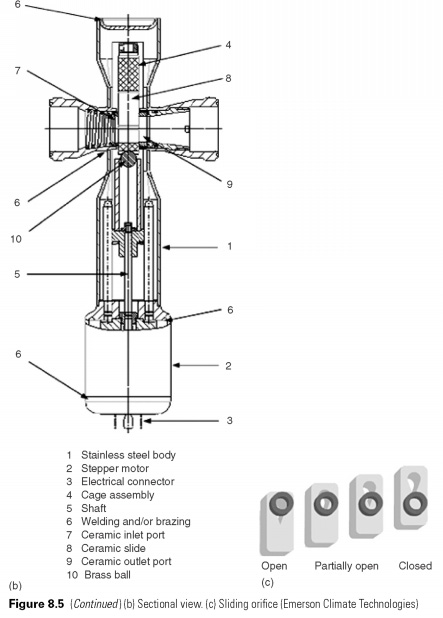

Types of electronic valve, for example, a continuous stream type, in which the size of the holes varies by a step motor, and with pulse-width modulation (PWM) type. In each case, the controller is used in combination with the valve. The controller is configured for the refrigerant and valve type, and it receives information from sensors of pressure and temperature at the outlet of the evaporator.

This allows overheating to be determined. Output signal to the valve initiates throttle adjustment. In the case of PWM valve connection between the opening and closing which determines the ability of the valve. The valve can be opened or closed, and every time in the interval of a few seconds will include the opening date, depending on the signal.

There is a third type of valve, which combines both of these functions. In modulating voltage is sent to the stress, improves actuator pressure of the container is increased, resulting in increased during the opening of the valve " vicious circle " of a fixed duration.

In each case, the control can be configured so that the valve remains closed in the event of power loss. At partial load or floating condensing pressure that occurs at low ambient temperature, the condensing pressure decreases. Thermostatic valves, as a rule, hunt, but the system of electronic components of partial load, the same stable as the full load.

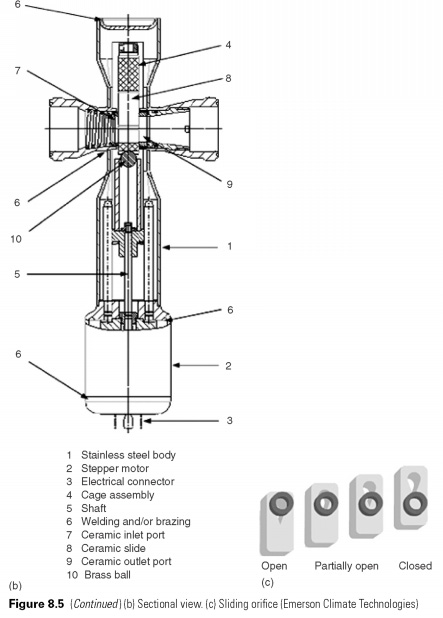

Continuous flow valve type shown in Fig. 8.5 . The valve seat and the slider is made of the solid ceramic. The shape of the valve slide ensures high performance linear capacity between 10% and 100%. Depending on the controller and its configuration, one control valve can be used for various control tasks. Possible areas of application include: expansion valve with superheat control of suction pressure control for performance management, liquid injection-de-overheating of the compressor, condensing pressure control and hot gas bypass control to compensate for excess compressor capacity and to ensure the evaporating pressure does not fall below the given value.

.... ....

|

....

....