Compressors

The purpose of the compressor in the steam compression cycle is to accept the low pressure of dry gas evaporator and raise its pressure, which in capacitor.

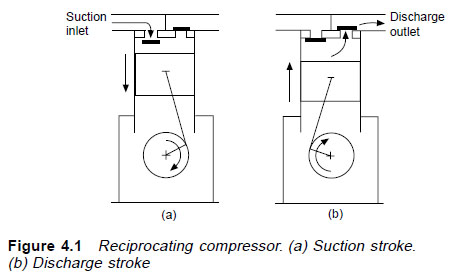

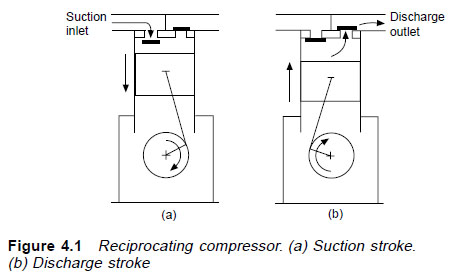

Compressors can be bulky or dynamic type. The General form of a piston compressor piston, being flexible, size, number of cylinders, the speed and the way drive. It works on the two-stroke cycle (see Fig. 4.1). As the piston descends on the suction stroke of the internal pressure falls until it is lower than in the suction inlet pipe, and the intake valve opens to recognize gas from the evaporator. At the bottom of the stroke, the valve closes again and the compression stroke begins. When the pressure in the cylinder above, than in the discharge pipe, the discharge valve opens and compressed gas, reports the condenser. Design of gas to the left at the top of the stroke must be re-deployed before a fresh charge may enter the cylinder.

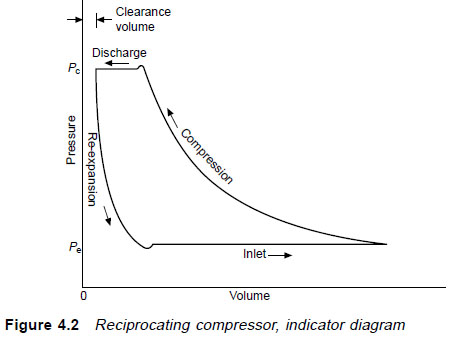

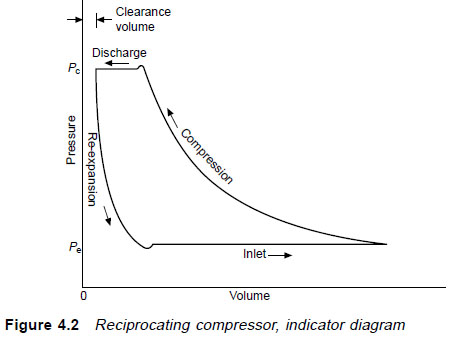

On Fig.

4.2, as well as in Chapter 2, for theoretical and practical cycles on the Mollier chart and volumetric efficiency).

The first commercial piston compressors were built in the middle of the last century, and have evolved from steam engines, which provided the tractor. Construction was first double action, but there was difficulty in maintaining gas-tightness of the rod, so the design turned to one-acting machine with Carter on the suction nozzle pressure, leaving only a rotating shaft, as a possible source of the leak, and it was hermetically Packed gland...

|