Piston Compressors

The majority of household, commercial and industrial HVAC/R systems use a compressor. They are classified in several ways:

- On the cylinders

- Number of cylinders

- Type crankshaft

- Construction (open/external disc available sealed, or hermetic)

The original source of energy for reciprocating compressors, as a rule, is a electric motor. Its rotational motion must be changed to reciprocating (there and back action in a straight line) movement. Tin change is usually done with the crankshaft and connecting rod. Rod connects the rod with the piston. Complete mechanism is in an airtight container named Carter. It is very effective. Its design resembles that of the automobile engine.

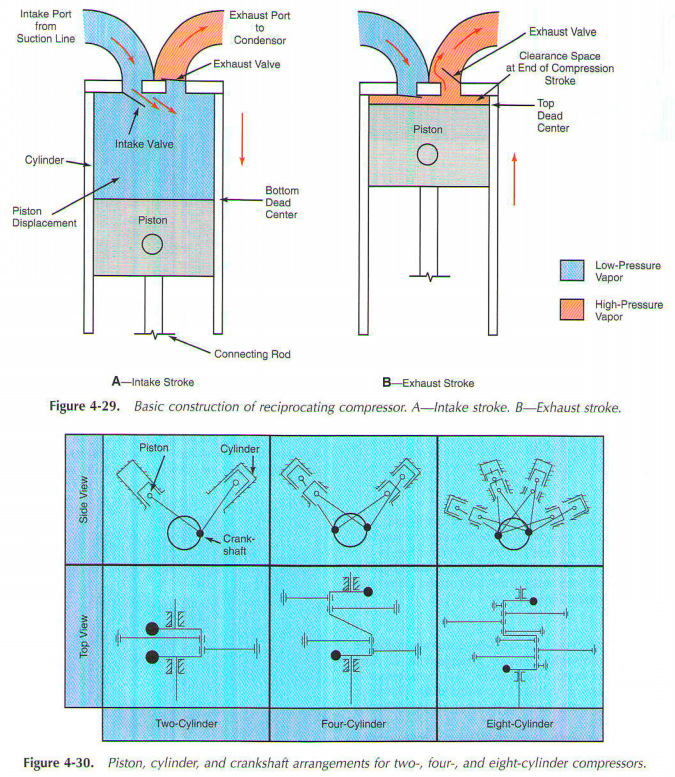

Basically, piston compressor cylinder and piston. Fig. 4-29 demonstrates principle of operation of piston compressor. On Fig. 4-29A, the piston moves down in the cylinder, It has moved refrigerant vapor from the suction line through the inlet valve.

From there refrigerant vapor moved into the space of the cylinder. On Fig. 4-29B, the piston moves upw7ard. She squeezed evaporation of the coolant in a much smaller space (free space). The compressed steam was pushed through the exhaust valve in capacitor.

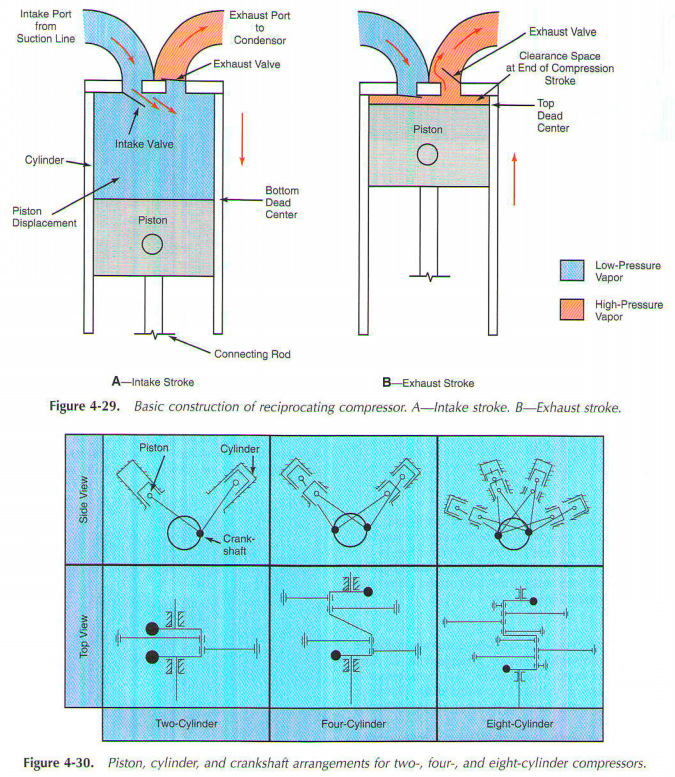

Piston Cylinder Crankshaft Agreement

Compressors can have more than one cylinder (. vlindec). In these compressors, crankshaft and cylinders are arranged to make the compressor as compact as possible. Fig. 4-30 illustrates some common cylinder crankshaft arrangements. More capacity of the pump should be provided for every rotation of the crankshaft. Most two-cylinder compressors use a parallel arrangement of cylinders and 180 of the crankshaft. While one piston at the top of the stroke, other piston is at the bottom. The other two-cylinder compressors have two cylinders in 903 V. See. Fig. 4-26. With this arrangement of cylinders, one-dirow crank is used.

Dual-power compressor is a Technology Compressor was developed by Bristol Compressors. This compressor uses special crankshaft design, Fig. 4-31. He has a rotary lobe that automatically sets itself up to allow the two pistons in the forward direction of rotation or, Fig. 4-31A. When the compressor is running in the opposite direction, the share of positions itself as a center axis of the shaft, and one of the pistons sitting idly by, figure 4-31B. Compressor cycles and less work for longer periods to its low capacity. A long cycle times decrease of start/stop cycles up to 75%, resulting in lower voltage dip and reduce the wear of the compressor. This ensures high efficiency and enables the system to extract moisture, which leads to a decrease in humidity and high comfort.

.. ..

|

..

..