Air condenser

The capacitor must be sized to match the estimated load at a maximum ambient temperature condition, but during typical operation conditions at air temperature 15C, the load will fall, because the load on the cooling system, as a rule, will be less and capacity of the compressor will, of course, less. Condenser which can be small, and require a high temperature condensation in the design condition, it remains to give an acceptable temperature condensation most of the time.

Materials of construction of aluminum fins, stainless steel tube for ammonia, or aluminum or copper fins on aluminum or copper pipes for halo hydrocarbons. Aluminium tube is not yet common, but its use will increase.

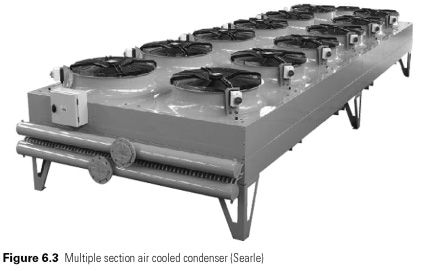

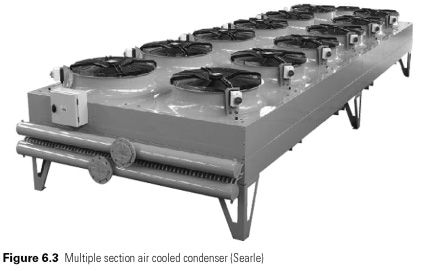

In connection with the high cost of materials, air-cooled condensers, the higher the temperature difference of cooling water, as is customary, and condensing temperature may be 5-8 K above the specified temperature of the cooling medium. Air-cooled condensers are very widely used in size from a few kW up to several hundred kW. They can be considered as a wall-mounted fan-coil units of air conditioners and on the roof of a large system, Fig.

6.3. They, of course, must be used on the land transport systems. They will also be used in desert areas where the cooling water supply is unreliable.

Often, you must change the air flow, for example, check that the condensing pressure drops too low for proper control on the part of low system to reduce noise at night time, or reduce fan power required at low temperatures. The control parameter typically condensing pressure and intelligent controller will reduce the output of the fan when this reduces overall power consumption, including compressors. Air flow reduction can be achieved by fans off for a few groups of supporters or by changing the fan speed. Single-phase fan motors can often be speed controlled with a simple measurement of pressure controller, which varies the voltage to the motor. Hot coil air will flow even with fan of downtime. Large capacitors can be placed in two or more sections to overcome over-capacity situations. The effective size of the capacitor is reduced by disabling the corresponding section.

Organization of the coil in sections allows capacitor to serve more than one system cooling. They may have different operation conditions or refrigerants. Most manufacturers offer units with two rows of fans: two-section heat exchanger can be included for this purpose.....

|