|

|

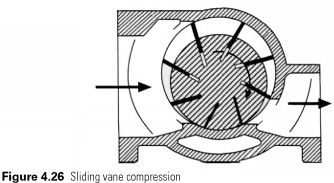

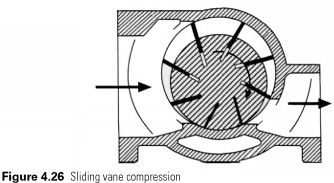

Sliding and sliding vane rotary compressors

Volumes between eccentric rotating blades of the rotor, and will vary with the angular position to provide a form of piston compressor (Fig. 4.26). Larger models have eight or more blades and do not require the intake and exhaust valves. The blades are held in close contact with the outer shell under the action of centrifugal force, and sealing improved by the injection of a lubricating oil over the entire length of the blade. Sliding vane rotary machines don't have a clearance volume, but they are limited in the statement emphasizes installed traction on the ends of the blades. While they were used in low-pressure discharge, such as the first stage of consumption, they are no longer widely used to compress the refrigerant.

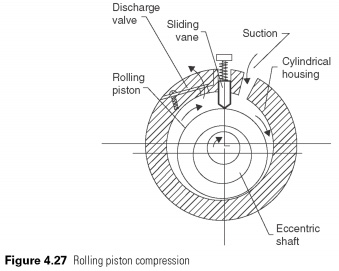

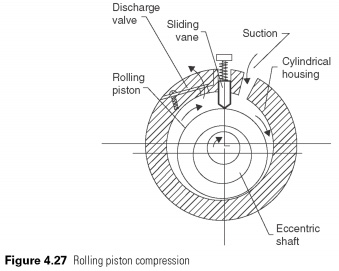

Lobed or rolling piston compressors have one or two blades that do not rotate, but are held by springs against eccentric rotating rollers. These compressors require exhaust valves. This type was developed widely devices, Autonomous air-conditioning and other similar applications, cooling capacity up to 15 kW (see Fig. 4.27).

.... ....

|

....

....