Compressor

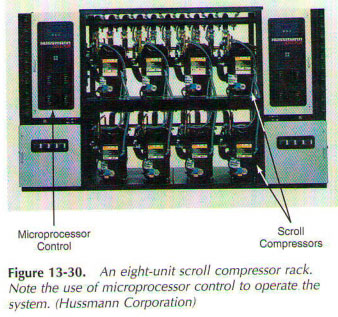

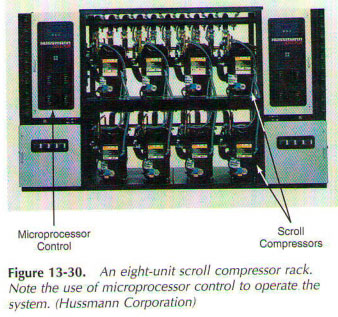

Commercial compressors are of two General types; external drive or sealant. Several scroll compressor refrigeration Cabinet shown in Figure 13-30. This device uses a microprocessor control system for monitoring and control of each compressor operation.

There are several types of commercial hermetic compressors. He has forced lubrication system. Some large units either hydraulic or electric unloading devices to control the number of cylinders pumping. The higher the load, the more cylinders used for transfer of vapor. Figure describes how he managed in the operation of a compressor station.

Another type hermetic compressor represents the welded motor-compressor design, nonfield good. These units are manufactured in sizes from 1/6 HP up to 20 HP Internal design varies depending on the size and manufacturer. Some spring mounted inside, while others use external mounting springs. In smaller units, as a rule, one cylinder. Larger units (1/2 HP and above) have two or more cylinders.

Small units engines can be two - or four-pole (single-phase). Three-phase motors are usually used by larger units.

Many combinations, types, and sizes compressors can be used to provide for pumping of various types and dimensions of the evaporator. Each compressor has a minimum and maximum:

- Revolutions per minute (rpm) for higher efficiency.

- Compression ratio maximum difference of pressure from the low and high side).

- Discharge temperature.

- The amount of gas that can pump.

Before using the compressor manufacturer's operating characteristics must be known. Many low-temperature systems use a cascade system. The first stage of the compressor can be reciprocating units, but rotary units. Rotary compressor pressure limit is about 45 psi compressor. It works very well with a compression ratio of 4:1. It also works well with a supply temperature of about 200F < 93C). >

Rotary has a high volumetric efficiency return valve is usually placed in the discharge. This prevents back-up of the refrigerant in the out-of-cycle. Non-return valve must be placed in the pipelines for the same reason. Compressors can have from one to twelve cylinders, There are many different cylinder arrangements: vertical, V, W, Y, X, or radial.

Internal unloaders normally controlled by oil pressure. Spring keeps the inlet valve open until the oil pressure increases. In this case, all of the intake valves work. Tt is also used to reduce pumping capacity during low loads. Solenoid valves are mounted in the oil lines, higher and higher. When the solenoid valve is closed, the oil pressure drops in the unloader. Intake valve remains open.

Low pressure switches work solenoids. Timer bypass breaker pressure system operates at full power for about a minute, every hour or two. External unloaders use the bypass at evaporator inlet, ensure suction pair is cool (de overheating)...

|