THE CHOICE BETWEEN SINGLE-AND TWO-STAGE COMPRESSION

Designer of low-temperature cooling system must decide whether to choose one or two stages of the agreement. It is difficult to imagine any object on which the first cost of the two-tier system, not more than one stage of the plant. Energy savings and other advantages of the two-stage design should, therefore, compensate for the higher cost of the first.

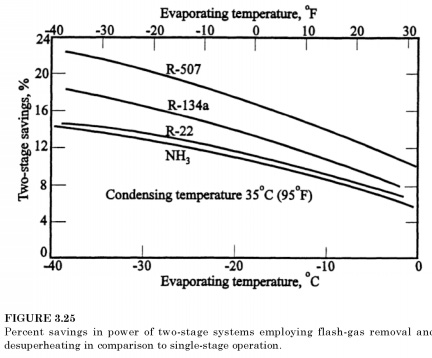

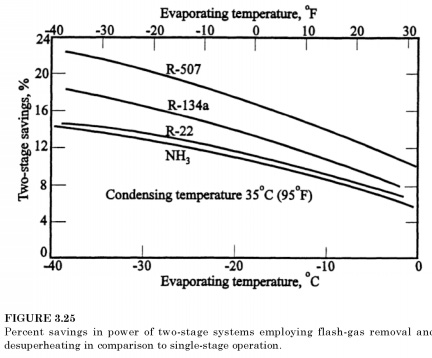

Fig. 3.25 shows savings in two stages of operation as compared to one stage, including flash-gas removal and intercooling, and asssuming ideal compression. The savings increase, because the boiling point of the drop, which is one of the reasons why the two-stage system so popular for low-temperature refrigeration. Designers usually begin taking into account the two-stage system in the evaporator temperature drops below -10C (15F).

The extent of savings achieved by two stages, as shown in Fig. 3.25, functions, properties of the refrigerant. Interestingly, the least efficient refrigerants in the single-stage systems have the highest percentage of savings (when converted into two stages.

In fact, two-stage boiling temperature -40C (-40F) of ammonia, R-22 and R-134a all are equally effective, although at one stage of the operation ammonia is the most effective, followed by R-22 and R-134a.

If the enterprise uses reciprocating compressors, two-stage structure may be necessary to limit the ratio of the pressure of the compressor to the typical value of about 8. If condensing temperature 35C (95 F)pressure equal to 8 exceeded at boiling temperatures as low as -6C (21F). This limitation on the pressure ratio does not cover screw compressors, which are able to work with coefficients 20. But another factor is that the compression efficiency, as figure 3.25 is based on 100%efficient compressors. Compressor efficiency deteriorates the pressure ratio increases, compressors on a two-tier system to work more efficiently. As an example the case of two-stage system where the evaporator operates in temperatures ranging from -40C (-40 F), in which the condition in Fig. 3.25 indicates ammonia savings of 14.5%. If actual compressors are considered, efficiency under one stage can be 68%, while in the lower compression ratio in the two phases of the operation efficiency of each of the compressor can be 75%. Savings during the consideration of the factual compressors and their ineffectiveness would Timb to 22.5%.

.. ..

|

..

..