Commercial refrigeration

Supermarket has a large number of individual food storage areas - coldrooms and showcase, which requires refrigeration. The original method was, as in the case of domestic food freezer, condensing unit, as a part of each office. Using the 'plugins' in this direction may lead to increase of temperature in the shopping areas, where the condenser heat input. This imposes additional requirements on air conditioning systems. To avoid this, remote condensing units, as a rule, are located in the Central plantroom, became widely accepted solution.

With the continued growth in the cooling load and the difficulty of providing adequate space for air circulation condensing unit, the compressor concept of updates (see Fig. 13.4) in cooperation with remote condensers was developed. Bank compressors provides for each boiling point, with a total pressure of condensation. This arrangement is very flexible, compressors switched logic controller to maintain the right conditions, regardless of the number of able to work in any moment. Grouped capacitors give the possibility of heat recovery from the discharge gas for heating of water, and in winter for heating the building.

Several defrosting methods are possible.

Off-cycle defrost not use any form of artificial thawing. The ice build-up, which may arise on the heat-exchanging surface of the evaporator is removed during the out-of-cycle equipment. This method is used mostly for vacation cabinets. Electrical defrost is simple in operation, control, and does not rely on any external services for the supply of thermal energy. This method is used for frozen displays. Hot gas defrost-a method in which the disposal of gas from the compressor taken to the evaporator to ensure defrost heat. Many of the hot gas defrost systems were installed, but security problems led to the adoption of electric defrost in most cases today.

There is no " one size fits all " for supermarket applications. There are situations when the integral plug-ins or condensing units are a good solution. This is especially true for small shops and petrol stations, gas stations, stores. With the increasing emphasis on refrigerant containment has been a shift towards the use of small, localized compressor preference to one remote plants (see Fig. 13.5 and 13.6). This type of installation uses less refrigerant and reduces the so-called parasitic losses, that is, the pressure drops and heat gains in the long suction lines connect remote areas of the plant. It is best suited to the building where the roof or wall space for the units, but this may not always be the case.

The requirement to provide adequate and unobtrusive cooling tightly Packed sales floor space remains a challenge for the engineers and transport refrigerant HFC through a long pipe works with many joints remains susceptible to leaks. Recognition of this problem within a certain period of time, and more recently with the introduction of the European F-Gas regulation, has driven innovation. They include indirect systems, where brine rather than the refrigerant circulates in a showcase. This is an effective but expensive solution and potentially more energy-intensive when the pump power and extra heat transfer losses are accounted for.

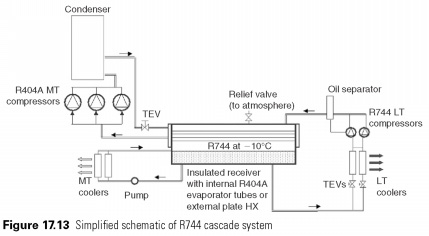

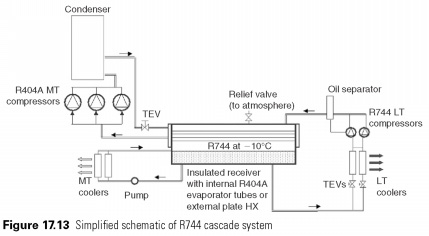

Recently, CO2 cooling been introduced in several of the study sites using the cascade system, Fig. 17.13 that allows CO2 pressure level to be limited 27 bar.

The receiver contains R744 (CO2) in the amount of approximately 10C in conditions of saturation pressure " 27 bar. Evaporator, consisting of the pipes inside the vessel, or an external heat exchanger, is used to reduce CO2 emissions. The evaporator is part of a circuit containing R404A (or other refrigerant), and the schema is used to maintain the temperature and pressure in the receiver. Liquid CO2 is pumped medium temperature cabinets where some of the liquid evaporates about 10C, resulting in a two-phase mixture back to the receiver. The second supply of liquid CO2 is sent expansion valves for low-temperature display, where it evaporates about 35C (12bar). As a result of R744 vapor is compressed to a pressure in the receiver, where it condenses. In such a system only liquid circulated cabinets sales on the floor CO2 and relatively small diameter high-pressure pipe takes less space than conventional refrigerant. Electrical defrost mode is used.

Experiments were made with CO2 TRANS-critical systems, and it is likely that success will depend on the heat from the cooling of the gas process, and return to the vapour compression cycle, which is more efficient at low ambient temperatures.

.. ..

|

..

..