Expansion valve

The expansion valve is a passive hole through which the liquid refrigerant forced by the pressure difference between the condensing and evaporation. Capacity ratings are given in catalogues of manufacturers and suppliers. Types of General use are:

- Capillary tube for small hermetic systems. These plants selected and cannot be changed.

- Solenoid valves with liquid level sensors or liquid level valves flooded evaporators.

- High-pressure valves, plus tube throttle valves for some flooded and low-pressure receiver.

- Thermostatic valves or electronic expansion valves, direct schema extensions.

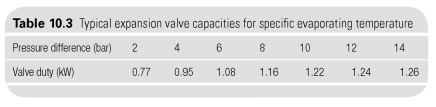

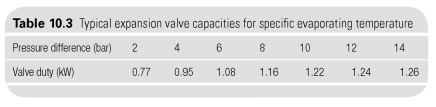

The trouble may occur with the choice of thermostatic valves type are normally used in a custom system. Usually to select a thermostatic expansion valve maximum debt and summer condensation condition, taking into account the pressure drop through liquid distributor in the case of multiple feed reel. Valve ratings given range of pressure drops, soE., for a number of condensing conditions for a particular refrigerant boiling point and States, as in Table 10.3 .

You might think that debt is changing the pressure drop of the fluid flow laws, but this does not happen, because the phase transition occurs, and the pressure drops. This means that the valve may be able to pass more fluid at low condensing pressure.

Conversely, if the valve is installed in a lower pressure drop (this may be condensation in the UK 20-25C), the valve will not grossly oversized for the maximum summer condition. Although no standards exist for valve rating conditions are usual for a state, of a nominal capacity of 38condensation C, 4boiling C 1 K hypothermia and 3-4 K overheating. Sometimes the data takes the form of a nominal capacity and reduction of correction factors.

If the thermostatic expansion valve is very tightly rated, the system will operate satisfactorily on the bottom of condensation condition in cool weather, with the strengthening of duty compressor and reduce power consumption. A growing awareness of energy Economics leads to more efficiently use this component. Suppliers are ready to help with advice and optimal choice.

The greatest difficulty arises where the compressor may fall to 33% or 25% of the capacity of the expansion valve is designed to control significantly reduced flow. In such conditions, thermostatic expansion valve can be unstable and 'hunting', with little loss of evaporator efficiency. Since the required duty, it is not very important, but this should be avoided. Possible to fit two expansion valves in parallel and to isolate one at partial load, but this mechanism, as a rule, is not required. Low condensing pressure operation should present no problems with floating-point or electronic expansion valves, as they may open for the passage of fluid flow in case of the correct size.....

|