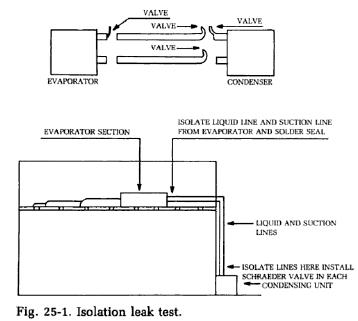

Insulation Test

Insulation test you need a four line access Schroeder valves with pig tails in the dryer nitrogen and nitrogen regulator. One of the features of inert nitrogen gas is that it does not depend on temperature changes, as refrigerants. The advantage of this test is that the pressure in the system will be the same when it is checked for a day or two later, regardless of the temperature. On Fig. 25-1 system is divided into four parts. Each segment was sealed access service valve hard soldered to it.

Nitrogran then assign each of the four segments using the collector and sensors. Place the exact amount of pressure required in each segment. As already said, may not exceed a specified pressure testing of the amounts maker installed on your device. R-22 systems, 350 psi enough pressure; for R-12, 250 psi pressure is enough. The important thing about this test is that the pressure of the amount should be the same in four segments. Nitrogen should be left in the system for several days, the longer the better. When you return to the unit, place your manifold sensors on each segment and check the pressure.

Block leak will natuBrally have the lowest pressure. This isolation test is expensive, but it once again confirms that the system of partitions is the place to be. Many times, this method shows that a leak in the condensing unit, which you have registered at the beginning. This test eliminates tearing things apart nothing. When you split system on this test, remember that you have to put it together again, so as not to destroy the joints of pipelines, where it will be necessary to have the system back together. If the leak is found in one of the lines connecting the condensing unit with the evaporator unit, the new line can be run instead of trying to repair the leak in the original. This test gives you this option, and remove all doubt as to where the leak.

Tests like this will detect a leak in the evaporator or the condensing coil. Then you can delete it from the device and seal the ends so that it can be immersed in water, as the inner tubes are tested to find memory leaks. Flow in the coil can be directly under one of the plates attached to a tube. Water bubbles will show exactly where the leak was. Then the plates can be reduced to make the repairs. You'll have to deal with copper, steel, aluminum or when making your repair. You should be familiar with the three materials. In addition to the silver solder and flux, it is advisable to wear brazing rods. Maybe a flux or pre-fluxed terminals can be used, if you store them in a dry place. Many of the steel components used in the areas such as condenser coils, receivers, batteries, oil separators, to name a few. Rust hole or crack, can be easily restored

by soldering brass ROAThe secret in any molten metal surface repair of the piece to be renovated, clean and dry. A lot of buns epoxy coated in the factory, to prolong their life. It has to be cleared from the area will be renovated, very carefully. Aluminium is widely used solder in the field today. Special solder, needs very low heat. It is expensive, but compared to the cost of evaporator coil or condensation coils, price solder cheap. The use of this solder takes practice and it is difficult to teach with the written word. In practice, the old first coil. Remember that the surface should be very clean, fluxed and low heat should be moved constantly above the repair zone. The application of oxy-acetylene torch is a must in this industry, and you need to practice to be experienced.

Other ways to repair aluminium, have appeared on the market, some of them work well. Compression type of connection is used, where a joint of steel, aluminium. The device works pretty well. Another type of repair of coupling two pieces of aluminum using sleeves, sealed in line once in the position of epoxy resin. This adhesive is activated by placing heat for a fitting.

....

|