Requirements and specifications

Oil properties, consider the behavior of the system, namely the return of oil from the compressor system, and its influence on the process of heat transfer in the evaporator and condenser. Part of the compressor designer's task is to provide lubrication for fitness, compressors and systems.

I n the working environment of lubricant is always a mixture of oil and refrigerant and therefore in its composition and properties are regulated solubility characteristics of pressure and temperature dependent. CFCs, HCFCs and ammonia refrigerant/mineral oil combinations, backed by years of experience; their properties are well known. Compressor designers used a combination of viscosity and excellent boundary lubrication (slippery) properties of chlorine-containing refrigerants to good effect in the design of the moving parts. With the advent of HFC refrigerants, it is necessary to move from mineral oils, synthetic oils, in order to ensure compatibility with the refrigerant and, consequently, adequate oil return from the system.

POE oils were selected for most applications, depending on their properties, the cost and availability. The CPT made of organic acids and alcohols, which together produce esters and water. The formulation of ether is determined acid structure. As its name implies, POE is a mixture of esters derived from a mixture of acids.

The behavior of lubricating oil in the refrigerant circuit and physical interaction with the refrigerant itself are the dominant factors in the development of schemes in General and evaporators, in particular. It should be noted that the solubility of ammonia in most lubricants is very low.

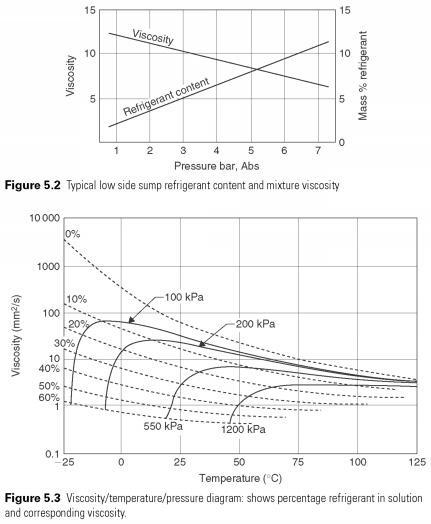

The degree of solubility of refrigerant in oil is desirable because the viscosity of the mixture in the evaporator reduced, allowing it to become more mobile, and that AIDS transport back to the compressor. The most important property for compressor operation is the viscosity solution for lubrication of bearings. As the low pressure varies with temperature in the evaporator, the refrigerant concentration changes, and this in turn affects the viscosity. Typical behavior for Halocarbon refrigerants is shown in Fig. 5.2 .

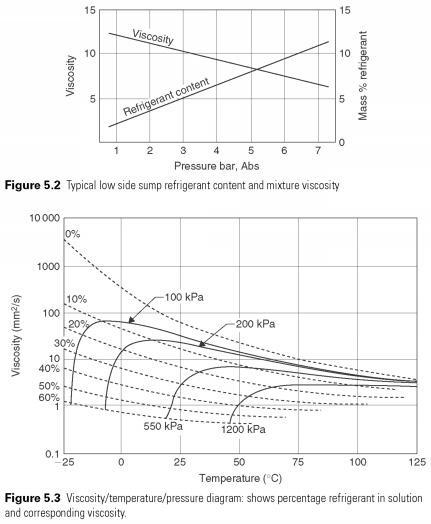

At low pressure of 1 bar, relevant evaporation, say, from -40C a small amount of refrigerant dissolved and it has little effect on the viscosity. Higher evaporation pressure, say, 6 bar, corresponding to 10C oil absorbs 10% of the refrigerant, which effectively reduces the viscosity of that half of the base oil and the carrying capacity is reduced. These effects are studied using the viscosity / temperature/pressure chart, the format of which is shown in Fig. 5.3. This scheme is just intended to illustrate the General form of the characteristic and is based on the refrigerant R134a and PoE. Specific data can be found in the ASHRAE Refrigeration links.

When liquid lubricants and liquid refrigerants are mixed together and helped to solve, homogeneous mixtures can be generated. In this case, the pair, as they say, is mixed with water prevailing pressure and temperature. In addition, two separate steps, forms, one of which is oil solution of other refrigerant-rich solution. In most cases heavier refrigerant-rich solution is below. This will cause problems on systems where the compressor in a cool place condenses and refrigerant in the Carter during shutdown. "When you start, oil pump, as a rule, would make a very low viscosity refrigerant-rich mixture. The crankcase heaters and pumping cycles are used to avoid this problem. This is not the case, ammonia, and is, as a rule, are not mixed with lubricants, except for small quantities and oil tend to accumulate at the bottom of evaporators, where it can be removed.

The desired properties for lubrication can be summarized as follows. Many characteristics that affect the refrigerant and therefore oil property cannot be considered in isolation.

- Adequate lubrication viscosity at high temperatures and high pressures in bearings and quite useful for sliding contacts.

- Resistance to chemical reaction or decay occurs in the conditions which will be faced. As a rule, high temperature and pressure in the discharge of compression. Oxidation resistance is measured point of ignition.

- The lubricant must be moisture and contamination-free as possible.

- Lubrication must be compatible with the materials used in the system. Special points of non-metallic flexible rubber and plastic parts, such as seals. The boiler can be used with ammonia.

- Viscosity of liquid at low temperatures, the parties must be low enough for adequate oil return.

- Solids should not be precipitated. Mineral oil may sometimes wax residue at low temperature; identified with the floc the time of testing.

- High electric resistance it is necessary for enclosed motors.

- Foaming characteristics should be considered.

- Availability, at an acceptable cost is significant.

To comment on the above, it should be noted that the characteristics of the grease in a real working environment can be tested only on real experience and/or tests. This is a tribute to the engineering effort compressor builders and installers systems that the transition to HFC refrigerants and polyester oils was very smooth and hassle-free process. Chemical stability shall be adequate in the presence of moisture and air, although the aim is always to exclude these contaminants from the system. Traces however, currently in practice, and this is discussed below. Excessive foaming not desirable when it is due to the rapid release of refrigerant in the compressor starts and crankcase pressure reduces the fact that it tends to lead to loss of oil in the system. Some foaming during normal operation and can help the distribution of oil in the compressor and reduce noise.....

|