Cooling and protection

Heat is generated in the process of compression, and the discharge temperature should be limited in order to avoid the risk of oil or refrigerant decomposition. Temperature discovered varies depending on operating conditions and refrigerant. In many cold suction gas, coupled with the loss of heat in the atmosphere, ensures sufficient cooling for small machines. For some operating conditions of the fan can be specified by the manufacturer. Refrigerants such as ammonia, giving high discharge temperature require the use of water-cooled cylinder heads. Oil coolers may be needed which can be water, air, or the refrigerant is cooled. Discharge temperature will tend to be higher when working with intermediate load.

Compressors can overheat if the mass flow becomes very low, for example, on the conditions resulting from abnormally low suction pressure. This may be the result of refrigerant loss. Low mass flow rate will also lead to a loss of oil in the system and the burden on the developer of the system to ensure adequate oil return, otherwise the lubrication will be broken.

Liquid refrigerant can enter the compressor when fault conditions, and this can reduce the viscosity of the lubricant, and in excessive amounts can cause serious damage.

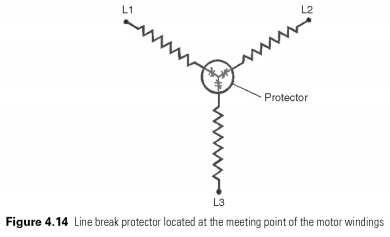

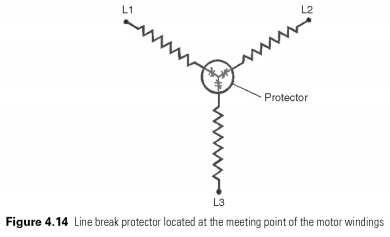

These problems may have the effect of reducing service life of the compressor, and tend to provide compressors with short circuit protection. The temperature of the oil and protection are the most effective and usually take the form of " cuts"that stopping the compressor in case of high temperature or insufficient oil pressure. Motor protection normal and closed types of engines, and may take the form of temperature sensors embedded in the windings. Small compressors internal line break protector, which is sensitive to temperature and electric current is sometimes used, Fig. 4.14. Each leg has a heater and a contact and all three of the opening and closing at the same time. It is located where the three windings of the motor to meet and all three phases taken in case of overheating and/or overload. Because it is built-in and domestic, no need to bring the wires back shell for external connections, and it can't be happened to be passing.

Some applications known to require compressor resist liquid return. For example, it is not economically feasible to provide preventive management system for small reversible air-conditioning to make sure that no fluid return to defrost. Here compressor manufacturer ensures that the compressor design life was tested to give many years of reliable operation under foreseeable conditions.

When you first start the cooling system can work at higher suction temperature and pressure than in normal conditions of use, and, as a consequence, higher discharge pressure, taking more energy. In addition, during the first seconds of the engine it is necessary to ensure sufficient torque to accelerate the compressor. Aid began devices are used for most commercial and industrial applications, and can take the form unloaded start bypass, or regulation of the suction pressure. On the electric side of the frequent requirement is to minimize electrical surge startup problems. Start device, such as a star Delta or part-winding start the engines. To open compressors, drive motors should be chosen according to ensure that this drop-down power and an allowance of 25% of normal. As a result, the engine will work for most of his life on something below 80% of rated power and a lower efficiency, low level of current and poor power factor. For semi-hermetic and hermetic compressors starting characteristics are determined to minimize the excessive size of the engine.....

|