Gage Recalibration

Most sensors to maintain a good degree of accuracy, despite the use of a daily and continuous processing. Because they are precision instruments, however, you must set up a regular program to test them. If you have a regular program, you can be sure that you are working with accurate instruments.

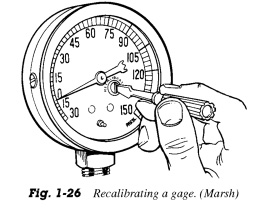

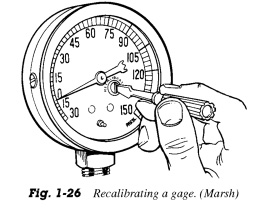

Sensors will develop reading errors, if they are dropped or subjected to excessive ripple, vibration or a spike in violence excess pressure. You can restore gage accuracy of adjustment calibration screw. Cm. Fig. 1-26. If the device has no calibration screw, remove the ring and glass. Connect the device checks and indicated with a certain accuracy same pressure source. Compare the readings at midscale. If the test gage reading the same as test-gage, delete pointer and " reset".

This type of adjustment on the index acts only as a pointer-to set the device. He did not restore the original even increment (linearity) pointer travel.

This is a more serious correction requirement is becoming more and more.

If your gage has recalibrator screw on the dial, as shown in Fig. 1-26, remove the ring and glass. Reset the pressure gage. Turn the calibration screw until the pointer is at zero. In gage will be as accurate as when it left the factory, if he has a screw to adjust the calibration. Resetting the dial to zero restores accuracy over the full range of scale readings. If you don't calibrate gage on any of these methods, take it to a qualified service technician for repair.

..

|