Plate heat exchanger

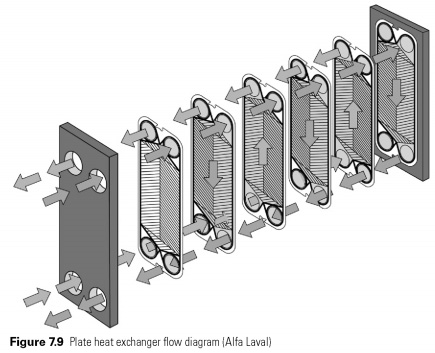

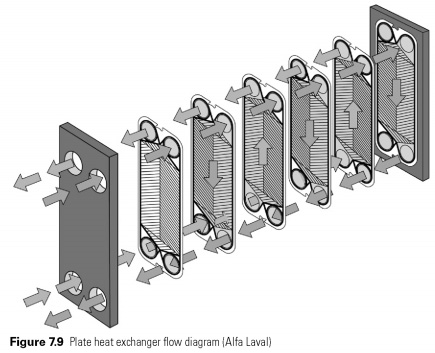

Plate heat exchanger evaporators now widely used. This type of heat exchanger consists of a series of herringbone corrugated plates, gathered to form a package (Fig. 7.9). In herringbone deepening located in opposite directions from each other in respect of each facing slabs. Brazed plate heat exchangers (BPHX), Fig. 7.10 plate, made of stainless steel with copper coating on one side. In the process of production, they gathered and held together until the end of the plate and heated in a vacuum. In melts of copper and rolled products at the points of contact seal the edge of the joints. When cooling buildings alternate with counter-flow of the channel is formed and separated only by a thin layer of stainless steel.

The amount of refrigerant contained in the heat exchanger of this type is about 2 liters per square meter of cooling, which is 10 times below, than for several handsets. This helps to keep low refrigerant and provides faster response to changes in energy demand.

Turbulence caused by the structure of the channel leads to very high heat transfer coefficients, as a rule, three to four times greater than with conventional tubular designs. Counter-flow temperature difference, near-perfect. Refrigeration BPHX always refrigerant channels surrounded by water canals, so that there is another source of water than the amount of refrigerant channels. The extreme of them are water channels.

A lot of configurations. If the channel height decreases or corrugation angle increases pressure drop and heat transfer rises. Increasing the length of the plates has a similar effect.

When used as a direct expansion of the refrigerant evaporator rate must be high enough to grab the oil that remains after complete evaporation of the liquid. Where conditions give rise to inconsistencies, the formation of an oil film on the surface in contact with the product may impair heat transfer. Overheating section have less effect, since the region is the sensible heat transfer and speed for the transportation of oil to drop this requirement.

It is important to ensure a good distribution so that the refrigerant enters all channels evenly. In BPHX should be mounted vertically with the refrigerant entry at the bottom. The pipe between the expansion valve and the entry point should be short and small diameter, so the speed of the fluid carries drops through the far plate. Some projects include distributors to assist in this process. Improper distribution may lead to unsustainable expansion valve behavior and reduce the evaporation pressure. Electronic expansion valves, which provide a continuous stream, such as the variable types of holes, suitable, but because of a small internal volume BPHX, pulse-modulated valve can give rise to unacceptable pressure fluctuations.

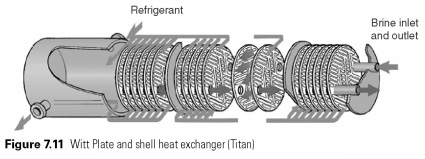

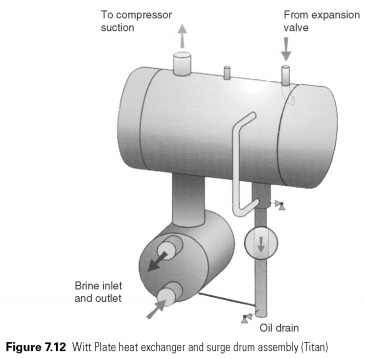

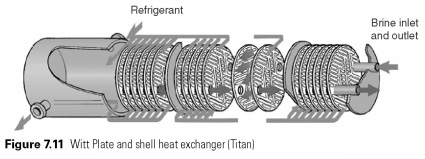

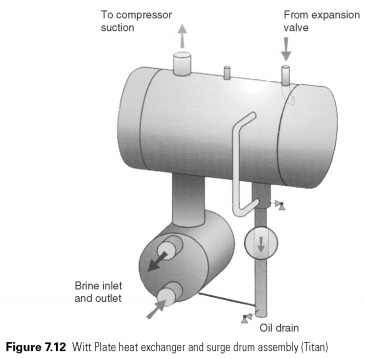

Additional settings you can use the plate and shell heat exchangers (Fig. 7.11)that work on a similar principle. In this case, welded structure is used, which makes this type of evaporator suitable for ammonia and carbon dioxide as a refrigerant. They can be constantly flooded with the refrigerant, working in conjunction with a sharp drum, in which fluid is metered by means of a float valve expansion. An example of an Assembly is shown in Fig. 7.12 .

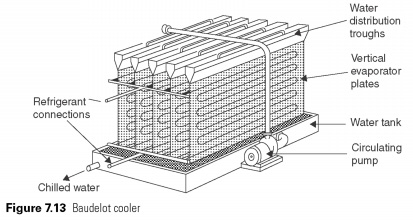

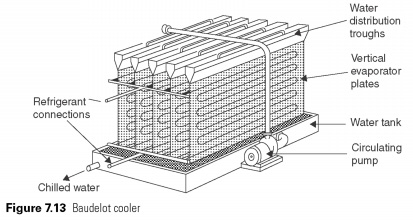

Where water is cooled close to freeze without risk of damage to the evaporator, the latter is usually organized over-tank battery and a thin film of water runs through the tube. The heat transfer is very high thin liquid film moving and, if any form of ice, he will be outside, to expand freely, and it will not damage the pipes. Such an evaporator is called Baudelot cooler (Fig. 7.13). It may be open, closed, dust shields, to avoid contamination of the product (e.g., surface coolers of milk and cream), or may be enclosed in a pressure vessel, as in Mojonnier cooler for soft drinks, which loads carbon dioxide, at the same time.

Some liquids, such as vegetable fats and oils and cream, ice cream mixtures, significantly increase the viscosity, as they are cooled, sticking to the surface of the heat exchanger. Evaporators for this debt is organized in the form of a hollow cylinder (see Fig. 7.2(b)) surrounded by refrigerant and having internal rotating blades which a defective product, as it thickens, introducing the clean surface of the product flow and driving cold insert to release.....

|