Measuring instruments

Static pressure in the channel are too small to be measured Bourdon tube pressure gauge, and inclined manometer normally used (Fig. 24.2). In addition, there are Electromechanical anemometers. Pressure when pressing the air duct must be normal air flow.

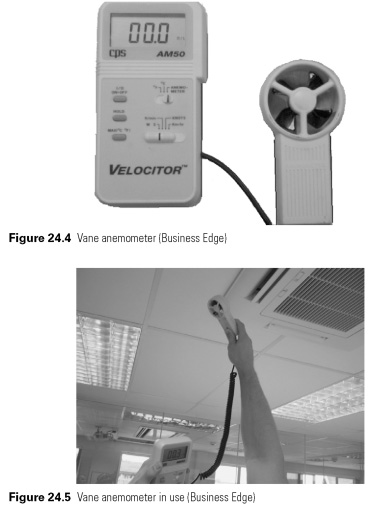

Tools for measuring the speed of pressure effectively convert this energy into the pressure. The sensor is used Pitot tube (Fig. 24.3)that go into the airstream and is connected to a manometer. External tube standard Pitot has lateral branches, which will be normal air flow, giving the static pressure. By connecting internal and external knock the ends of the gauge difference is the speed of pressure.

Sensitive and accurate gauges are needed for measuring the pressure of below 15 PA., that is equivalent to the channel speed of 5 m/s, and the accuracy of this method falls below 3.5 m/s. The Pitot head diameter should be no more than 4% of the duct width, and head to 2.3 mm in diameter can be obtained. Gauge should be carefully aligned.

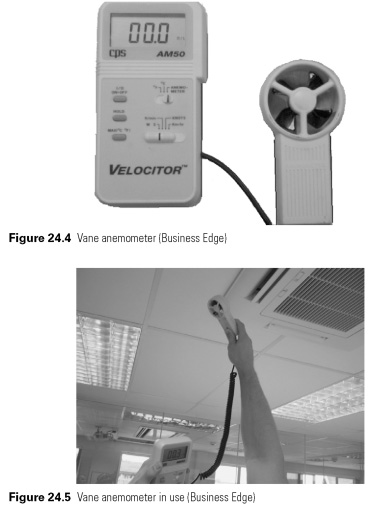

Air speed can be measured with the help of mechanical devices, the most famous of which is the vane anemometer (Fig.

24.4 and 24.5). The air becomes blades meter, and the air flow is read from the handheld device. These tools need to be calibrated, if not require high accuracy. Accuracy 3%very much in demand.

Hot wire anemometer detects the cooling effect of the air moving over a heated wire or thermistor, and converts the signal speed. Speed of the air flow down 1m/s) can be measured with a stated accuracy of 5%, and lower speeds can be specified.

Air flow will not be uniform across the surface of the duct, speed is higher in the middle and lower near the duct person, where the flow is slowed by friction. Readings must be taken on a number of positions and the calculated average. Testing methods and positions for measurement are discussed in British Standard BS1042. In particular, the airflow will be very uneven after bends or change the shape, so measures should be taken in a long, straight duct.

More accurate measurement of air flow can be achieved with attachments or plates with holes. In such cases, the measuring instrument imposes considerable resistance to air flow, so that the compensation fan is required. This method is not applicable to the installed system, and is used primarily as a tool for the development of factory manufacturing of packages, or for testing the fan...

|