Water-cooled condensers

The higher heat capacity and density of the water make it the ideal environment for the cooling of the condenser and, compared with 350 kW plants mentioned above, the flow of just 9.8 l/sec. Small water-cooled condensers can consist of two concentric tubes ('double pipe'), refrigerant, being in any of inner tube or annual lus. Configuration can be straight, with the return bends or headers, or spiral. Two-trumpet system of the condenser circuit inrush current (media flows in opposite directions), to get the most exposure to cold, because the cold water will meet outgoing liquid refrigerant.

Large in size, with a water-cooled condenser requires closer pipe-laying, to minimize overall dimensions, in the form of a shell-and-tube with water in the pipes (Fig. 6.4) . This design is very flexible mechanical design and occurs in all sizes from 100 mm to 1.5 m in diameter and lengths from 600 up to 6m, the last of which the length of the produced pipes. Materials can be selected for the application and the refrigerant, but all of sheet steel common to fresh water, with Nickel, silver or aluminum brass tubes for salt water.

In some farms the size can be achieved through extended surfaces on the refrigerant side, as a rule, in the form of lower integral flippers, formed on the tube.

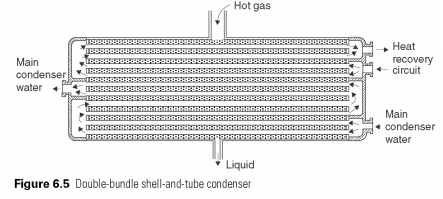

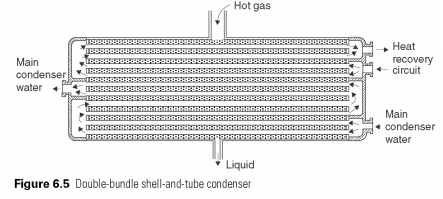

On the water side, vortex strips can be established for the promotion of turbulence, but these interfere maintenance cleaning and not so much " for". Speed of movement of water in the pipes is approximately 1 m/s, depending on the size. To support this speed, the partitions are in the end caps to direct the flow of water, the amount of plugs in each 'pass'. Some capacitors have two separate water circuits (dual beam. 6.5), using warm water of the same chain as reclaimed heat in another part of the system. The basic kit rejects the excess heat. Where the mass flow of water is not limited (sea, lake, river or cooling tower), the temperature increase through the condenser may be below 5 K, since this will reduce head pressure on the price of only large water pumps and pipes.

However, if water is used once only through him, and then deflected into the drain, the range can be significantly higher, possibly, 10-12 K.

.... ....

|

....

....