Multiple Unit

Several compressors, operating in parallel, should be carefully tap to ensure proper operation. The suction pipeline in parallel compressors must be designed so that all the compressors operate at the same suction pressure and oil is returned in equal proportions to the work of compressors. All suction line should be included in the common suction header to return the oil to each Carter as uniformly as possible.

Intake manifold should be above the level of the compressor suction bays so that the oil can enter the compressors by gravity. The title should not be below the compressor suction inlets, because it can become the oil trap. Branch of the compressor suction line must be removed from the header. Care should be taken to ensure that the return of the network from the evaporators are not connected into the intake manifold to the form of crosses with the branch of the compressor suction line. Intake manifold must be performed in full size along its entire length. Horizontal UPS various compressors must be the same size as the intake manifold.

No reduction shall be made in the branch of the suction line of the compressor until elevation reached.

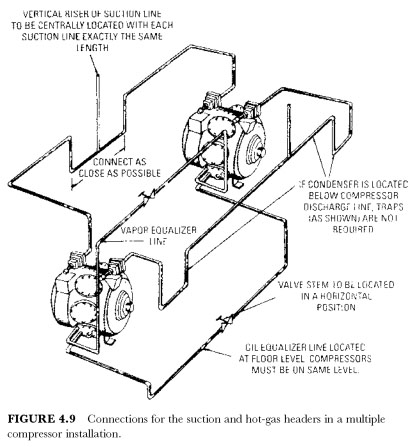

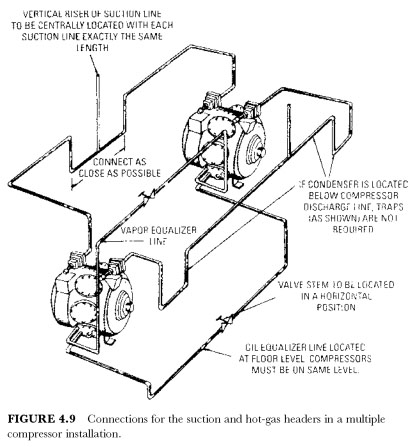

On Fig. 4.9 shows suction and hot gas title arrangements two compressors operating in parallel. UPS for each compressor of the common suction header must be horizontal, and to ensure equal distribution of oil and prevent the accumulation of liquid refrigerant in the idle of the compressor in case the slop.

Insulation Of Pipelines

Insulation is required for refrigeration piping for prevention of condensation of a moisture and prevent the flow of heat from the ambient air. The desirable properties of insulation that he should have a low coefficient of heat transfer, be easy to use, have a high degree of consistency and provide protection against the penetration of air and moisture. Finally, he must have reasonable expenses for installation.

The type and thickness of insulation depends on the temperature difference between the surface of the pipe and ambient air, as well as the relative humidity of the air. It should be clear that, although the system is designed to operate at high suction temperature, it is quite difficult to prevent colder temperatures, arising from time to time. This may be due to transfer of some fluid from the evaporator or operation of the valve evaporator pressure. Interchangers is preferable to isolation in this case.

One of the most secure pipes, insulation is available pressed cork or rock cork corresponding thickness. Hair-felt insulation can be used, but great care must be taken to properly sealed. At temperatures above 40 degrees Fahrenheit, felt or similar isolation may be used, but success depends on proper sealing against the penetration of air and moisture.

The liquid refrigerant lines carry much higher temperature of the refrigerant than the suction line; and if the temperature is higher than the temperature in the space through which they pass, without isolation, is usually required. However, if there is a danger of liquid lines running below ambient temperature and causing condensation, they shall be isolated by condensation will not be acceptable. If they inevitably will have to go through the heated spaces, such as those located steam pipes through the boiler rooms and other, then the liquid lines should also be insulated to ensure a solid pillar in the expansion valve.

There were four types of insulation is used before the opening of the modern insulating materials. Those that you can encounter that were in common usage refrigerator for pipelines, cork, rock cork, felt, and hair felt...

|