Absorption Refrigeration Systems. Ammonia water (NH3-H2O) ARSs

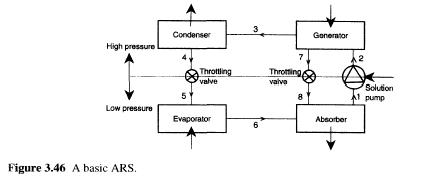

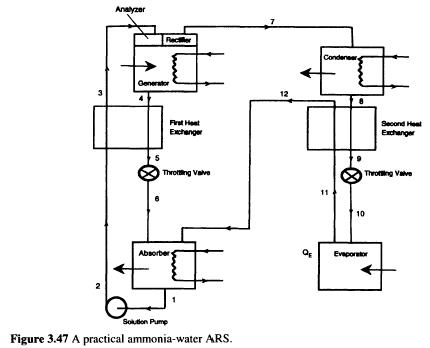

In practical ARSs download one or two heat exchangers is very common. Fig. 3.47 is of practical absorption refrigeration system with the help of a working liquid ammonia as the refrigerant and water as the absorbent, with two heat exchangers. As can be seen, in addition to the two heat exchangers, this system uses analyzer and rectifier. These devices are used to remove water vapor, which could arise in the generator, so that only ammonia steam goes to the condenser. The system shown in Fig. 3.47 uses the internal capacity of the water to absorb and excrete ammonia as a refrigerant. The amount of ammonia vapours that can be absorbed and held in aqueous solution increases with increasing pressure and decreases with increasing temperature. His works are in the same system shown in Fig. 3.46, except analyzer, rectifier, and heat exchangers. In the absorber, water absorbs ammonia on the temperature of the condenser provided by circulating water or air, and, hence, strong solution (about 38% of the ammonia concentration) occurs.

Because of physical limitations, sometimes full balance saturation cannot be achieved in the absorber, and a strong decision, leaving absorber, cannot be completely saturated with water, and its pressure and temperature will require.

This strong solution of the absorber is to solve the pump (the only moving part of the system), which increases its pressure and provides a solution to the generator through a heat exchanger. Pumped a strong solution enters the generator through a heat exchanger where strong solution is heated before it is discharged into the generator of ammonia. Please note that the pumping energy required is only a few percent of the whole refrigerating energy demand. Generator, which is heated by energy source (saturated steam or other heat source through the heating coils or tube bundles), raises the temperature of the strong solution, causing ammonia separate from it. The rest of the weak solution of (about 24% concentration of ammonia) partially absorb water vapor coming from the analyzer/rectifier combination drains into the expansion valve through a heat exchanger. Then strangled in absorber for further cooling, as he picks up a new charge of ammonia vapours, thus becoming a strong solution. Hot ammonia in the vapour phase generator driven out of solution and rises through the rectifier for possible separation of the remaining water vapor. She then enters the condenser, and is available in a liquid phase. Liquid ammonia is in the second heat exchanger and lose heat in the cool of ammonia vapours. Pressure of liquid ammonia is decreasing in the throttle before it enters the evaporator. The loop ends when the required cooling load is achieved in the evaporator. Cool of ammonia vapours received from the evaporator is held in absorber and absorbed. This absorption activity reduces the pressure in the absorber and causes pairs, which will be removed from the evaporator. When the couple becomes a liquid that decision releases both its latent heat and thermal dilution. This energy release should be continuously scatters cooling water or air. Heat introduced in the absorption system in the generator (from steam heat) and evaporator (actual cooling mode) should be rejected " outside". One thermal emission occurs in ammonia condenser and other thermal emission occurs in ammonia absorber. Reabsorpion ammonia in a weak solution generates heat, and, unfortunately, this heat has to be rejected, so that the process of absorption can function. Ammonia water consists of water and ammonia. Water can easily absorb ammonia and stay in solution with normal temperature, so absorber has a cooling cooling water or air. Evaporated ammonia generator went through distilling column, where ammonia is concentrated in almost pure ammonia vapours before you go to the condenser. One day turns into liquid ammonia she drove into the evaporator, low-pressure side, where ammonia again turns to vapor, while picking up heat from the closed refrigerated space. Ammonia vapour is then absorbed into the absorber, to complete the cycle. The ammonia-water ARSs, the most suitable shock-absorber is a film-type absorber for the following reasons : * high heat and mass transfer rates,

* well, and

* large concentration rates. ..

|