M.O.P. valves

As we have shown, the usual TRV used remote sensing bulb, which always has some of the liquid refrigerant. This can cause problems during the cycle, and when the system starts, especially for air conditioning.

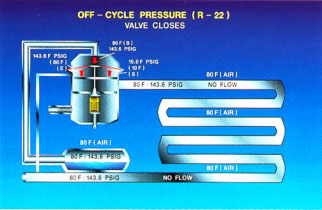

When the compressor cycles off, the liquid refrigerant remaining in the evaporator continues to boil for a while. If the compressor does not remove pairs produced by this evaporation pressure in the evaporator is rising quickly. It will stabilize the pressure, which corresponds to a temperature of ambient air vaporizer. For example, suppose that the air around the coil 80F. selection pressure 80F saturation temperature for R-22 is 143.6 pounds per square inch. This pressure is via the external equalizer line on the bottom of the diaphragm. Assuming that the sensing bulb is also exposed to 80F air, the same pressure on the top of the diaphragm. Starting with a gas pressure above and below the diaphragm are equal, spring bends pressure on the diaphragm upward; this causes the valve is closed.

When starting the compressor, evaporator sends the refrigerant vapor in the 80F saturated suction temperature of the compressor. This continues for a period of time before the new fluid flowing into the evaporator controls the temperature to the normal range of about 30F 50F for comfort air conditioning work. High inlet temperature causes excess power consumption of the compressor, which will cause the overload of the compressor motor. If the overload of the compressor motor continues, it will also lead to the damage of the compressor due to high discharge temperature.

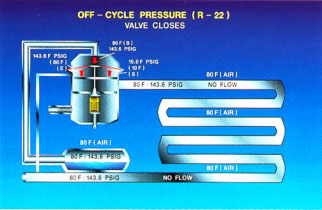

Another difficulty encountered in the launch is the result of remote sensing pressure light is not limited. He can climb as high as the air temperature around him permission. For example, in the previous case, 80F air around the sensing bulb placed 143.6 PSIG force above the diaphragm. When the compressor cycles ago, the evaporator pressure below the diaphragm is quickly reduced. Therefore, the light pressure above the diaphragm becomes a powerful opening force capable helmet valve is fully open. As a result, the liquid refrigerant is likely to flood the compressor before the valve regains control.

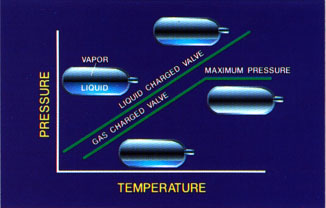

Because of these complexities and others, almost all air-conditioning systems with thermostatic valves limit the maximum pressure that can develop in the evaporator. They do it with pressure limiting valves, also called "Maximum Working Pressure valves, or just M.O.P. valves. Some styles limit the maximum operating pressure in the evaporator by mechanical means, such as a spring. Others achieve the same result using the limited refrigerant in the sounding of the ball valve.

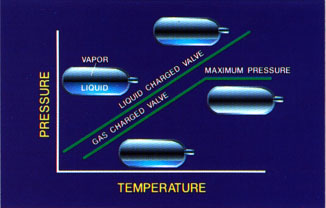

The valves shown so far, not been a sufficient amount of vapour refrigerant in sensing lamps, tubes and area above the diaphragm valve that there is always a liquid refrigerant into a ball. For this reason, the term "Liquid-Charged Valve" is sometimes used. Society with limited cost valve, on the other hand, M.O.P. valve, which has enough liquid refrigerant included below a pre-selected maximum working pressure (and temperature, that is connected with it). Higher pressure and temperature of the refrigerant in flasks, tubes and in the space above the diaphragm of all pairs. Increasing the temperature of the steam in the production of only a slight increase in pressure. For all practical purposes, when the gas valve, the pressure on the upper aperture stops increasing, when the temperature sensing reaches a certain limit. This solves the problems with residual liquid at the inlet of the compressor and start...

|