Avoid cooling

There is no sense to design an effective system if the load becomes unnecessary, and so the starting point to ensure that the load is the absolute minimum. This requires a critical energy survey process, the cold store operations or the building with air conditioning. The aim of this study is to determine the elements of the cooling load, and ways of reducing each element to a minimum, without prejudice to the cost of doing so. Such an assessment may not be accurate, but the need at this stage to deliver these cooling systems in some order to find what proportion of the total burden may be reduced by any form of treatment. Load elements

- Lowering the temperature of the product.

- The conduction of heat through the building construction; consider better insulation.

- Direct solar radiation in the cooled space; consider the possibility of shading.

- Convection heat gains from penetration, the opening of the cold store doors; consider castles in the air and ensure only disciplined access.

- Heat from auxiliary devices - fan motors, pumps, defrosting.

- Lighting - efficient equipment and switching the schedule.

This energy is payable in two times - up to put it in and then take it again.

Next, find out if free cooling can offset part of the load. The term " free cooling " is used to describe any method that does not require mechanical cooling, although it may not, strictly speaking, absolutely free of charge. It can be used when the wet bulb temperature is below the required level of temperatures of cooled space. Recognizing that the evaporative cooling may not always be practical: there are still opportunities for free cooling throughout the percentage of the year, when the outside air temperature are low and heat must be removed from the building. The increase in the share of fresh air is one of the ways to reduce the load with an air distribution system.

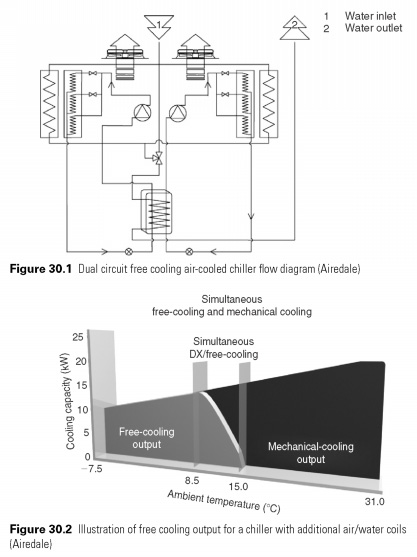

Chilled water circulation in the building may be pre-cooled external air to the cooling down process of decomposition. An example of free cooling chiller air conditioning circuit is shown in Fig. 30.1 .

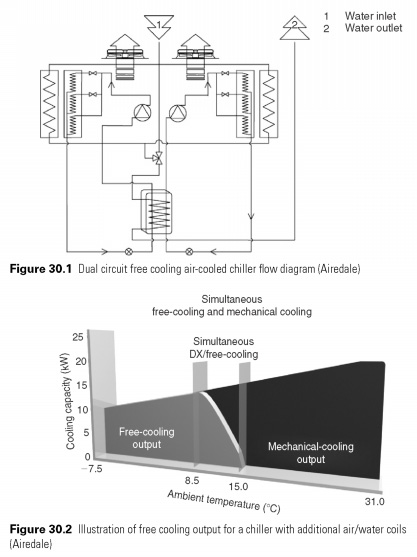

The water cooled passes from the entrance at the top of the evaporator (as shown in the bottom part of the scheme) using the 3-way valve. During normal operation, 3-way valve directs all evaporator water. In this example, there are two identical capacitors, and each capacitor has three refrigerant coil and additional water coil. When falls the ambient temperature reaches a certain point, the water is directed in these coil 3 way valve and becomes a pre-cools the surrounding air before passing through the evaporator. In the result, the air temperature may be sufficiently low to enable all cooling run directly from the cold outdoor air and refrigerant circuits idle. Saving illustrated in Fig. 30.2.

Cooling water can be made without running compressors and fans with the thermosyphon system, as described Pearson (1990) and Blackhurst (1999). When the ambient temperature is at a lower temperature than chilled water, moisture can condense at a pressure below boiling pressure in the chiller. Having capacitor above hmm, the liquid can be done to return hmm gravity. Hmm, should be carefully selected, but need not be special. Plate and shell coolers or flooded shell and tube chillers can be used. Direct expansion of the pipes in the shell coolers are designed for TEV work not suitable because the refrigerant will not boil and circulate in nature in them.

Evaporative condensers cooling refrigerant towards the ambient dewpoint, allowing more thermosyphon cooling in summer than air-cooled condensers. One attraction of the thermosyphon system is the possibility of using backup chillers even when the other chillers have compressors running. This is done by connecting chillers series on the shore with leading hmm be the last in the line, and receive partially chilled water from the non-self-propelled those upstream.

.. ..

|

..

..