Service Valves

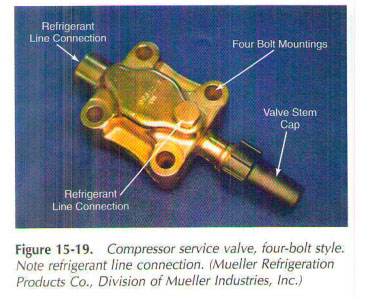

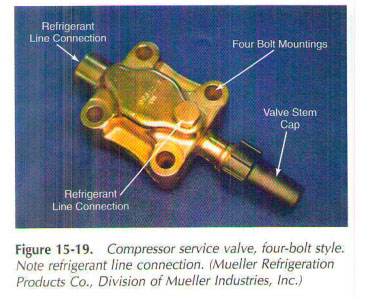

Service valves must be leakproof, where the valve is a valve. Packing is made of lead, graphite and other materials. Packings of a different design of the valve. During their replacement, proper packing should be used. This four-bolt fastening clothing style valve. The surface is slightly recessed for ease of bolt tightening.

Most of the rooms valves have a body made of brass and steel barrel. Stems are prone to corrosion and evaluation gland valve and / or the packaging. Always clean and oil valve before enabling It. This corrosion, especially in damp places can be reduced. Fill valve body with a clean and dry refrigerant oil to replace the plug. This should be done each time the service valve is used. This oil should be specified refrigerant oil for this machine.

Service valves in industrial units, must be kept in good condition. Three things you can do to ensure a good service and valve life:

- Match the correct operation of the valve wrench size to the valve stem to prevent Stripping valve.

- Support package so that the valve will not leak.

- The oil flow sensor connection each time when sensors are used.

Occasionally, after some time, these valves have to be replaced.

Pipe thread of the valve calibration holes can become worn and leakage. This results from reduced. Fill valve body with a clean and dry refrigerant oil to replace the plug. This should be done each time the service valve is used. This oil should be specified refrigerant oil for this machine. Service valves in industrial units, must be kept in good condition. Three things you can do to ensure a good service and valve life:

- Match the correct operation of the valve wrench size to the valve stem to prevent Stripping valve.

- Support package so that the valve will not leak.

- The oil flow sensor connection each time when sensors are used.

Sometimes, after some time, these valves have to be replaced. Pipe thread of the valve calibration holes can become worn and leakage. It is connected with frequent installation of flexible line fittings. Fittings are inserted in the holes of the sensor can be given a thin layer of solder, hi this way, the disease can often be eliminated. When cracking valve, always use a fixed key (not ratchet). This is done to ensure the valve can be quickly closed again if necessary.

Sometimes a service valve is in such a state as to be useless, hi such cases, the recovery of refrigerant or isolate it in another part of the system and replace the valve. Many external storage systems service valve liquid receiver (LRSV). Some LRS three-way valves. This allows a technician to the charge of liquid refrigerant in the system. When syslogd valve, remove the valve capif the valve. Loosen the service valve packing nut one turn. Next, clean the valve stem, before turning it on. Turn the valve stem approximately 1/16 turnover. Tighten the nuts of the seals, and replace the valve cap.

Rotary valve stem back slightly valve prevents from "freezing" against his seat. This condition is sometimes leads to a broken valve stems. Transducer installation the opening of the socket, tighten the plug. Never overtighten a cold sensor connect the hot valve's service. It can lead to freezing connect to the saddle. When you use the valve wrench on these valves apply turning power gradually. Adjustable end or fixed-open end keys are not recommended for service of the valve stem. Only a special connector, called keys, wrenches should be used.

If the sensor connector is frozen in the room valve, it can be dropped. Firstly, the heat outside the valve body with the flame of a torch. Be careful not to overheat. The heating will cause the housing expansion valve. As a result, it will weaken the body thread grip on the plug. In wTench can then be used to loosen the valve stem. Access valves are often used on the inlet of the evaporator or liquid line of the Bay. They are a little forward (downstream) of the refrigerant management and on both sides of automatic valves in the system. (These solenoid valves include, bypass valves of hot gas defrosting valves and dryers.) Need more convenient service outweighs policy, having a minimum connections.

.. ..

|

..

..