Outdoor units

The main concern with outdoor units keeps the thermostatic expansion valve is operating at full capacity in cold weather. The capacity depends on the pressure drop across the valve. If the condensing pressure for R-12 reduces from 102 psi, 90F (32C) 56 psi, 30F, valve capacity will fall. (Not enough liquid refrigerant will flow.) Refrigeration temperature inside the appliance can then rise too high. In addition, the low pressure drop can lead to short Cycling of the capacitor. Condensation temperature and pressure can be in good operating levels by changing the structure. The unit is made almost fill the condenser tubes with fluid. lust enough condensation on the surface of remained to maintain the pressure.

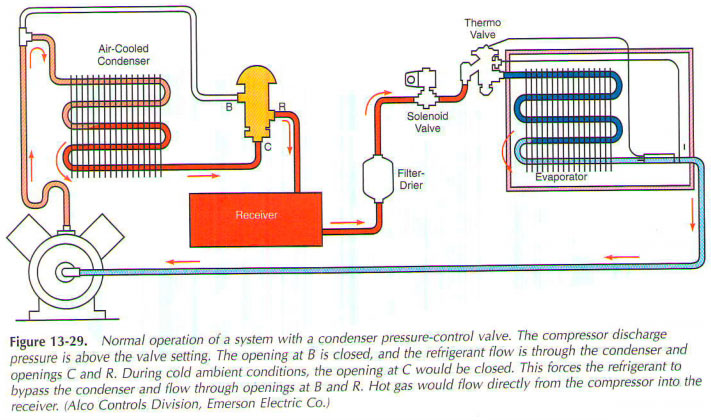

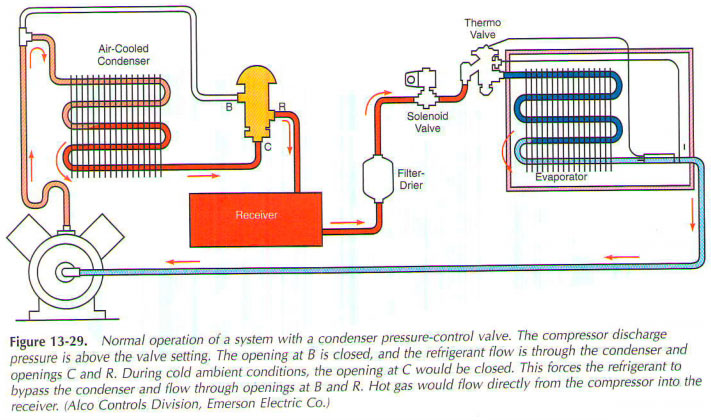

Pressure limiter valve on the outlet of the condenser will not open until valve condensation pressure to reach a proper level. When the pressure rises, limiter valve open and allow the fluid to leave the condenser. The installation specification must be examined carefully. The receiver must hold enough liquid refrigerant to the flood most of the capacitor in the winter.

It is also necessary to hold still refrigerant during the warm season. Another way to keep up pressure to close the capacitor case airflow louvers as the pressure drops. Pressure sensitive device makes it.

This pressure, the device will move rod building up pressure. The link will open the blinds. As the head of the reduction of pressure in the rod will move back and start to close the blinds. Condenser fans can work with the blinds closed, or they can be turned off when the blinds near the end point. In the capacitor, with ambient temperature-controlled.

Other system off the fan capacitor, when condenser pressure drops to the minimum level. Lower the fan speed control when the head falls pressure. Electrically controlled modulation-fan speed are used for tin cans goals. This system operates with a thermistor on the condenser and special fan motor. Electrical heating elements, sometimes located around the receiver. This will help receiver temperature warmer than the temperature in the Cabinet. If it was allowed to become too cold, the receiver will act as the capacitor.

Some systems use a bypass from the compressor to the receiver. This diversion channel hot refrigerant vapor to the receiver to keep it warm. The bypass has a check valve installed in it, to make sure one way flow of refrigerant. The compressor should be kept sufficiently warm in cold weather. This is to prevent dilution of the oil with liquid refrigerant. Heat is provided by means of electrical heating elements in or around the motor of the compressor. They are controlled by the thermostat for switching the heating element about 50F (. This heater, as a rule, has 100 watts to 200 watts of power.

Outdoor unit may not function adequately in strong winds. In these conditions, the built-in capacity to overcome the low-temperature environment may not be sufficient. When a strong wind can prevent the throttle and the fan operation. The cooling effect can be more than an electric heating element can overcome. The unit must be installed in a position to avoid the harmful effects of high speed cold winds. It should also be from the weather, and also possible in particular, the electrical components.

Head pressure control valves are often used. These are usually controlled by the thermostat. Low-pressure switch may not cut it, because the condenser pressure below the cut-in pressure. The refrigerant can then transfer the condenser. This is because then it will be a cold part of the system. Non-return valve is often used in the output capacitor. This prevents the flow of refrigerant cold receiver.

As noted earlier, some systems flood the condenser with liquid refrigerant at low ambient temperatures. This helps to maintain a high condensing pressure. When the condenser pressure decreases, one closes the valve on the outlet of the condenser. Capacitor then begins to fill with liquid refrigerant. This action reduces condensation surface, and condensing pressure will grow. Hot gas is allowed to bypass the receiver (about 20 psi pressure difference). This raises the pressure in the receiver and increases the flow of liquid refrigerant for evaporators.

Valve has two openings, and C. As one closes, another opens, if located in a cold place, the receiver may need an electric heating element. This allows the system to work effectively. These valves shall be of such size that the system performance. Avoid excessive pressure when testing for tightness. Valve bellows may suffer damage. Keep the pressure at or below 200J psi. System, as a rule, is charged with two times more refrigerant, as would be necessary without condenser flooding. Year-round operation requires the receiver with the possibility of storage of all this extra refrigerant during the summer. In addition, for service, the recipient should be twice the normal size. This will allow him to keep all of the refrigerant.

Compressor may also collect small amounts of liquid refrigerant cycle. Trap may be necessary in the discharge line of a compressor. Inverted trap may be necessary in the output capacitor.

.. ..

|

..

..