On the basis of steam-compression refrigeration

If the liquid is injected into the vessel, which was originally a vacuum and walls constant temperature of it will evaporate immediately. During the latent heat of vaporization, will come from the side of the vessel. The effect of cooling is the starting point of the cooling cycle, which will be addressed in this Chapter.

As the liquid evaporates, the pressure inside the vessel will grow until it reaches the specified maximum temperature valuesthe saturated vapor pressure (see section 2.8). After that, no more liquid evaporates, and, of course, the cooling effect will stop. Any further introduced the liquid will remain in the liquid state in the bottom of the vessel. If we now remove some of the vapours from the container, by connecting it to the pump suction, pressure will fall, and this will cause more water to evaporate. Thus, the process of cooling can be provided in a constant. We need a suitable liquid, called the refrigerant container where evaporation and cooling take place called the evaporator and the pump to remove vapors, called, for reasons that will become apparent later compressor.

System, as developed so far, of course, is not practical, because it involves a steady flow of refrigerant.

To avoid this, you need to convert the process repeatedly. In turn the steam back into a liquid, it must be cooled with any environment on hand for this purpose. It is, as a rule, water or air at a temperature much higher than the temperature of the environment is cooled in the evaporator. Steam pressure, corresponds to the temperature of condensation, therefore, should be a lot higher than the pressure in the evaporator. Required step up pressure is provided by the pump, acting as a compressor.

Liquefaction of the refrigerant is in the condenser, which is essentially a container external cooling by air or water. Hot high-pressure gas-refrigerant is served on the condenser and melted in it. Since there is a gas at high pressure in the condenser, and liquid refrigerant exists under the same pressure, easily complete cycle, providing needle valve or other adjustment device for injection of the liquid in the evaporator. Is an essential component refrigerant plant is called the expansion valve.

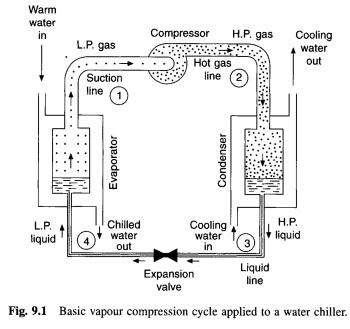

This basic vapour compression refrigeration cycle shown in Fig. 9.1, which shows used for water cooling kit.

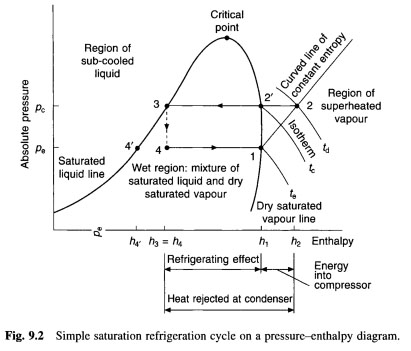

Figure 9.2 shows the changes in the state of the refrigerant as simple, basic vapour compression cycle occurs. Coordinates scheme absolute pressure and enthalpy but to explain cycle and describe the schema, you must first of all consider the thermodynamics of the subject.

.. ..

|

..

..