Heat Pipe

The concept of " heat pipe was first developed near the turn of the century. The first heat pipes were simple devices, but they sparked the imagination of many engineers because of their incredible speed and capacity for heat transfer.

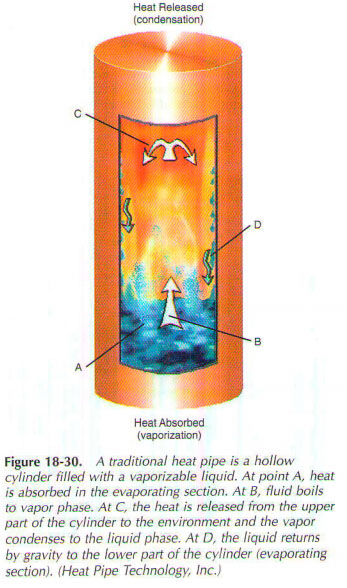

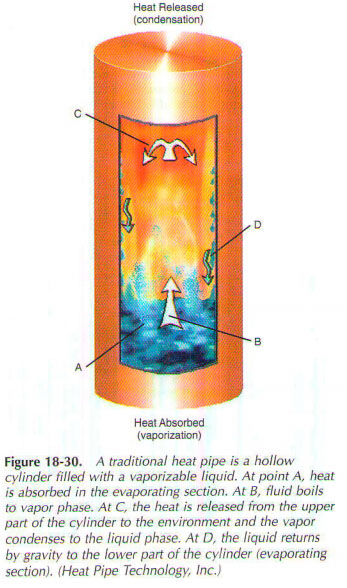

At the beginning of heat pipes were hollow metal tubes, which were sealed at both ends and contained a small number of evaporation of liquids, such as alcohol. Pipe contained in the "wick" for transportation through the capillary fluid front one end of the tube to the other end and were evacuated before being charged with a small amount of liquid to evaporate. When the heat was applied to one end of the pipe, it vaporizes the liquid inside the tubes. Steam distribution of the length of the tube to the other (cooler) end. There, the steam is condensed into a liquid and returned by capillary at the other end, where it evaporates again, repeating a new cycle. The process of absorbed heat of evaporation and condensation process of released heat. In other words, the tube was a heat pipe, taking away the heat from the one end and release it to another through repeated cycles of evaporation and condensation.

This process continued until, as the temperature difference existed between the two ends, the manufacture of heat pipes heat transfer devices.

The uniqueness of heat pipes is that the process of heat transfer is carried out at an incredible pace, which makes heat pipes one of the most passive heat transfer devices known. The principle of a heat pipe is illustrated in Fig. 18-30.

Although the principle is simple, the actual manufacture and use of heat pipes that works well is not easy. At the beginning of the thermal pipes wicks made of porous materials, which ranged from the fabrics to the metal grid. None of the wicks lasted very long. Continuous expansion and contraction due to sudden temperature changes broke them quickly and detached them from the inner wall of the pipe, affecting the ability to transfer heat. Because fabricadon was expensive, only for special applications, such as NASA, were seen as a viable uses.

In 1980, Khanh Dinh completely reconfigured heat pipe base structure and patented the process. This process led reducing the cost of manufacturing. In Digne Principle of a Heat Pipe was to design a heat pipe in the form of a loop.. By creating a cycle back and forth movement within the tube was eliminated. Instead, one way of fluid displacement was created that was extended by the pressure difference between the section of hot and cold section cycle. Heat transfer in a loop reached a speed that have never been reached before.

The second major breakthrough was the use of loop heat pipes in the system of conditioning. The result was twofold: air conditioning systems of best dehumidification, the reduction of indoor relative humidity, and at the same time decreased cooling load compressor allows substantial reduction in energy consumption. These advantages are especially useful in humid climate. Applying the principle of a heat pipe for air-conditioning systems, drying and efficiency was significantly expanded, with the removal of moisture increased by 30% to 50%. In Digne Principle of a Heat Pipe with respect to air conditioning systems. The air conditioner is the first to meet precool section " heat pipes, causing evaporation of phase-change fluid contained within. Fast heat transfer, the heat pipe moves heat energy (usually 8-12F, 4.5-6C) around a cooling coil for heating section of the heat pipe where it is replaced in the air flow. Total precool and heat the effect is similar to a normal (active heat) systems, providing greater removal of moisture through the cooling coil.

A unique feature of the heat pipe is the ability to perform this effect passively, without the use of any mechanical device or additional costs of energy. More importantly, no heat is added in the conditioned space, both active heating systems...

|