Steam Jet Cooling

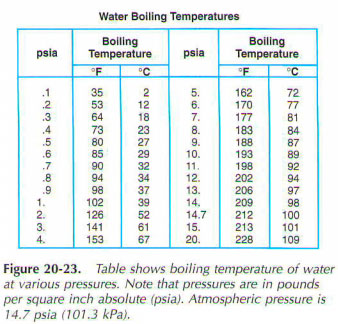

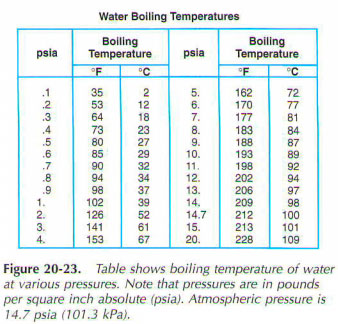

Steam jet cooling uses water as a refrigerant. The pressure on the surface of the water decreases to lower the boiling point. At a pressure of 0,2 psia (10 mm RT. century), the temperature of boiling water 53F (12C). Steam jet is shown in Fig. 20-24. Ejector draws water vapor from the surface of the water in the evaporator. This causes the evaporator pressure drop. Ejector, reduces pressure in the evaporator. The pressure is reduced until the water would evaporate at the right temperature. And vaporized, it absorbs heat and cools the water balance in the evaporator.

Steam pressure ejector nozzle should be about 150 psi (1030 kPa). Sometimes the steam is condensed in a different location, for the following reasons:

- To recover some of the heat from the steam.

- To restore water to steam.

- To reduce the pressure, so that it will not be a "backup" in the steam jet cooling chamber.

Pressure in the condenser not shown. This will be about 3 psia (21 kPa, 160 mm Hg). Pressure, 3 inch, corresponds to the temperature of vapor condensation, 141F (6).

Evaporation of water in the evaporator reduces the temperature of the remaining water. Pumps circulation of cold water for 40F 70F (4 to 21C), in the field of cooling.

These systems usually have a capacity of 100 tons or more. This ability provides a large supply of steam at a high pressure. It also provides a large supply of water for cooling of the condenser.

Steam jet systems are often used in air conditioning. They cool the water used in certain chemical plants for gas absorption. The cooling temperature provided by the steam jet mechanism, usually between 40F and 70F (4C and 21C). Temperatures below 40F impractical because of danger of freezing.

One application of steam cooling jet is the removal of water from dilute solutions containing juices. Orange juice can be concentrated in this way. Steam jet cooling does this by changing the water with orange juice and not providing water makeup. The process is not boil the juice at temperatures of about 212F (100C). Therefore, vitamins are stored in full force.

.. ..

|

..

..