The Central train station, in a combination of air and water cooling

Cooled air from the Central station system serves the purpose of ensuring the proportion of fresh air needed, and, bearing thermal energy from space. These functions can be separated using a much better liquids for the last. As the heat at temperatures above 0C obvious choice liquid-water, brines are used for certain purposes. Central plant is now necessary for the chilled water through the supply and return pipe, plus a much smaller amount of fresh air. There is no air return air ducts may be needed.

The chilled water will be supplied to the input of the number of air-handling units, each the size of a suitable areas where conditions throughout the area can be satisfied by the air flow of the air conditioner. This limitation led to an increasing tendency to reduce the size of the zones to offer the widest range of comfortable conditions within the space until the units to serve in one room or part of a room. Such units are made in wall-mounted form of perimeter or ceiling form to cover the open areas.

(See Fig. 28.8.) Larger units may be free-standing.

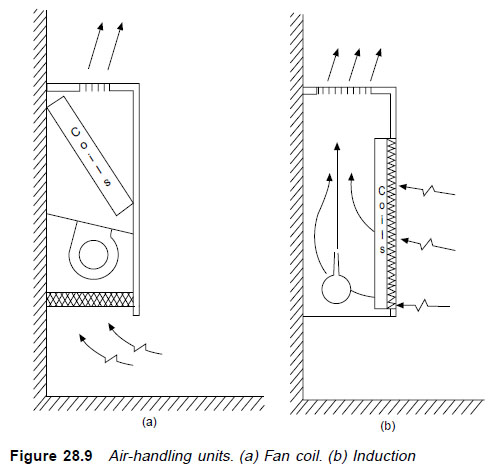

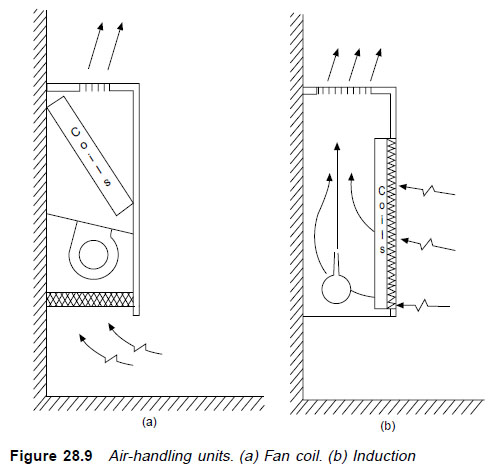

Two methods are used to circulate the air in the room above the chilled water coil. In the first, an electric fan draws air through the filter, and then passes it through the coil, before returning to space. The fan can be before or after the coil. Fresh air from the plantroom can be introduced through this device, or elsewhere. The coil is normally operated with fin temperature (ADP) below room temperature of dew point, so that some latent heat is removed, coil, which requires a condensate drain. Multispeed fans usually, so that you can reduce the noise times a light load.

The second method uses pressure energy of the primary (fresh) air supply to call the number (Central) air circulation. This air at a pressure of 150-500 PA, is released through the nozzle in the coil Assembly, and the resultant velocity at the outlet from 16 to 30 m/s seizes or induces the air in the room to give the total circulation in four or five times more than the initial offer. This additional air passes over the chilled water coil. Most induction units wall for perimeter cooling, but they were adapted for ceiling mounting.

Induction units, latent heat production can usually be handled by the primary air and they work with dry coils. Some systems have been installed in having a high latent load that removal of a condensate on a spool.

In climates that have clearly defined in summer and in winter, heating, if necessary, can be obtained using fan coils or induction units, supplying warm water to the coil instead of cold. Some variations of this can be achieved through induction systems, which can sometimes cold primary air with warm water, or Vice versa, giving the degree of heating-cooling choice.

Most climate, but in the middle of the season unstable weather so, heating and cooling may be required on the same day, and it emphasizes the building with large Windows, which may need in chilling winter days. For these applications, the instruments must have a continuous supply of both chilled water and hot water and a suitable control to choose one or the other, without a loss. Usually it implies the existence of two separate coils and four pipes, separate chilled and hot water circuits. (See Fig. 28.9.)

An alternative system, lower cost, three-pipe system. Chilled and warm water flows of the coil, and chose the number thermostatic valve for cooling or heating of the debt, as required. Water coil outlet passes through common third return the receiver to the plantroom. In peak periods, cooling, very little warm water is used and may be of little or no loss of energy mixing of the water flows...

|