High-efficiency Furnace, the Sequence of operations

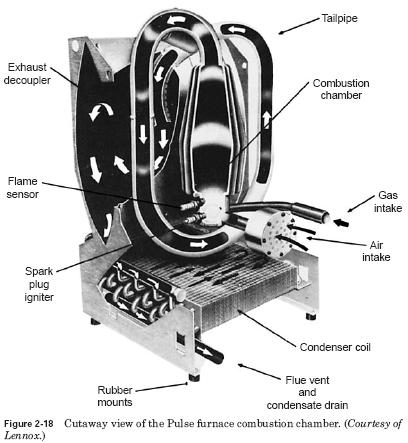

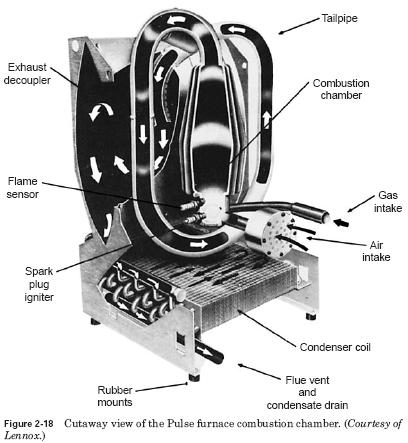

The demand for thermal energy, the room thermostat initiates clear operation blowers for pre-purge cycle 34 C, with the subsequent switching off the ignition and the opening of the gas valve. As there is a fire, a flame sensor senses the proof of ignition and turns off the power from the spark plug and clean the fan (see Fig. 2-18). Furnace blower operation is initiated 30 to 45 seconds after combustion ignition. When the thermostat is satisfied, the gas valve is closed, and purge blower is activated for a purge at the end of the welding cycle 34 seconds. Furnace blower remains in operation until the set temperature, the setting [90F (32C)] fan control is achieved. In case of loss of flame happen until the thermostat is satisfied, a flame sensor management will hold three to five attempts to re-ignition to lock the device. In addition, the loss or combustion air intake or exhaust flue will automatically shut down the system.

..

|