Refrigerator Commissioning. Evacuation

It is important, halogen cooling systems that all traces of air, non-condensibles and moisture be removed. If this is not done, then the presence of air or non-condensibles will lead to abnormally high discharge pressures and elevated temperatures, resulting in the conditions relating to the high operating pressures mentioned earlier. Air in the system will also mean that a certain amount of moisture in the air, will be distributed with the refrigerant in operating conditions. This moisture can freeze in the outlet of expansion valve or capillary fluid to prevent the refrigerant flow to the evaporator when the filter-dehydrator to become saturated. When the system was tested for tightness pressure, traces of nitrogen may be present in aggravate and high discharge pressure condition. There are two ways in which the system can be evacuated deep vacuum method, and the method of dilution. Deep vacuum method To meet the requirements of the pollutant in the system, a good vacuum pump is necessary.

At normal temperatures in vacuum 2 Torr should be done with a single vacuum cycle. The length of the vacuum cycle can vary considerably: the larger the installation, the more cycle. This can be left to the commissioning engineer, as provided in accordance with company policy, or a specific period may, at the request of the customer. Obviously, a large vacuum pump will expedite the procedure. It is not unusual for the system to stay on the vacuum within 24 or 48 hours or even several days to make sure that it is completely free from contamination. The advantages of vacuum that (a) will not be any appreciable loss of refrigerant other than the final trace impose a fee, and the leak test, and (b) you can return the trail of the refrigerant charging system (see Chapter 16, relating to contaminants and recovery of refrigerant). Also, the immediate environment, contaminated refrigerant vapour, so it's hard to hold final test for leak when the system is removed. This will be evident when compared with the dilution method. The method of dilution Dilution or triple the method of evacuation must be carried out using ofn (free oxygen, nitrogen) and not a trace free. 1. The initial charge of nitrogen must be retained at least 15 to 30 minutes. This can be evacuated in a vacuum 5 Torr.

2. This vacuum is then broke with another ofn charge that will allow it to circulate in the system.

3. Re-evacuate and charge the system with refrigerant. This repetition may be unnecessary, but after a single or double evacuation small pockets of non-condensables may still be involved in the pipeline system or controls. By repeatedly breaking the vacuum with ofn these centers will be dispersed or diluted ofn.

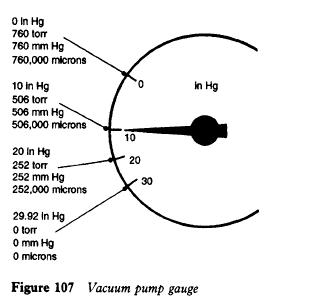

After each evacuation pump should be switched off, and in a few minutes after the calculated period, vacuum measurement. The system should then be left for another 30 minutes, and was reading taken. The increase in pressure means that there is a certain amount of moisture. In no case compressor system used for evacuation system. Comparison of vacuum gauge the scale shown on Fig. 107. Please note that 1 Torr = 1 mm Hg = 1000/zm Hg and micrometers are called microns.

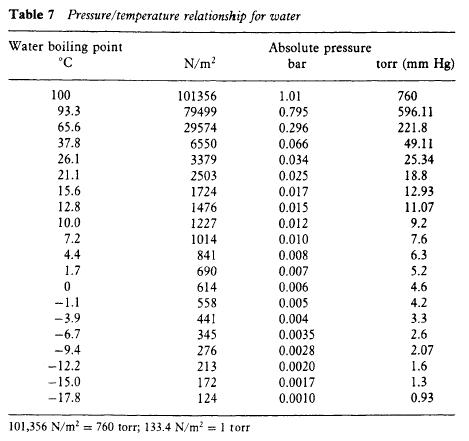

Fig. 108 shows a typical connection diagram of the vacuum pump for deep evacuation. During the evacuation system evaporator fan(s) can be operated and defrosting systems switched on the heating cycle in order to raise the temperature in the evaporator. Heaters should not remain energized for a long time in case of overheating of the evaporator and possible damage. It is also very important to ensure that none of the parts of the system are isolated from the vacuum pump. Fig. 109 shows triple evacuation arrangements. When the pump is running, isolator valve should be open, service valves of the compressor, in the midway position, the liquid stop valve receiver, and refrigerant cylinder valve is closed. Both valve manifold must be opened. When they break the vacuum to the vapour pressure of the refrigerant, make sure that the pump shut-off valve is closed. Table 7 shows the pressure/temperature relationship to water. During the evacuation system, remember that there should be adequate temperature difference .between the ambient temperature and water to ensure that the heat required to evaporate water.

..

|