Lubrication

Lubricating oils, which were developed specifically for piston and rotary compressors for refrigeration. As a rule, these are mineral oils, which is completely dehydrated, wax-free, and nonfoaming. They have a viscosity that is best for refrigerant and temperature refrigeration. (Viscosity influence on the ability to flow at a given temperature). Some refrigeration oils contains additives to improve the lubricating properties. Supplements can also increase the viscosity of the oil properties.

Piston compressors can be lubricated either burst or pressure (flow rate) system. In the splash system, Carter filled with the correct oil to the bottom of the main bearings or in the middle of the bearing crankshaft. On each crankshaft revolution, crankthrow, or eccentric, failures in oil. It splashes of oil at around inside the compressor. Oil is thrown on the wall of the cylinder and the piston pin bushings. He is also thrown into the small holes, where he can get into the bearings.

This is an excellent system for normal use in small compressors.

Some compressor rods little failures or scoops, attached to the lower ends. These scoop a small amount of oil and slung it around the other parts. Clearances between moving parts must be less in this system types. Noisy bearings, will occur in small gaps, than in the pressure in the system. This is because there is no oil under pressure to cushion the bearing surface. Feed force or pressure in the system uses a small pump oil. Pump pumps oil to the bearing, lower rod bearings, and in some cases, piston pins. This is a more expensive system. Pump is required. In addition, the crankshaft and connecting rod, you must have oil passages, drilled in them. With the pressure system, the compressor gets better protection from oil. It will also run quieter, although it has a large bearing clearances.

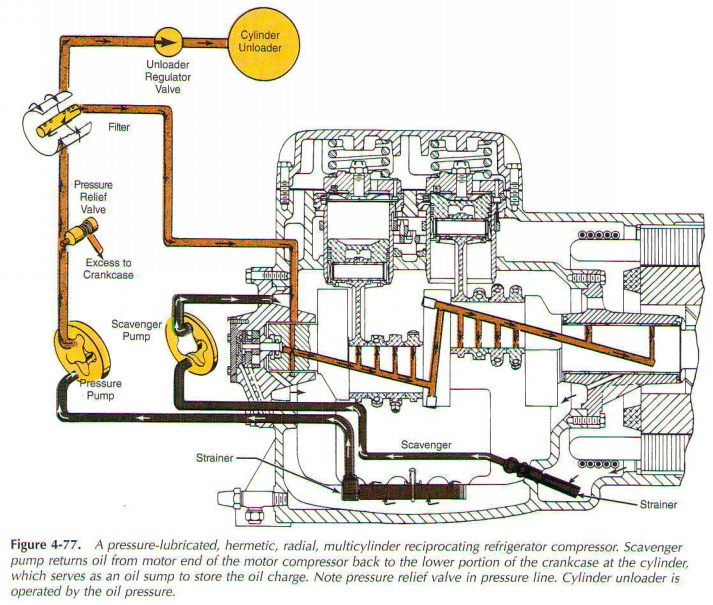

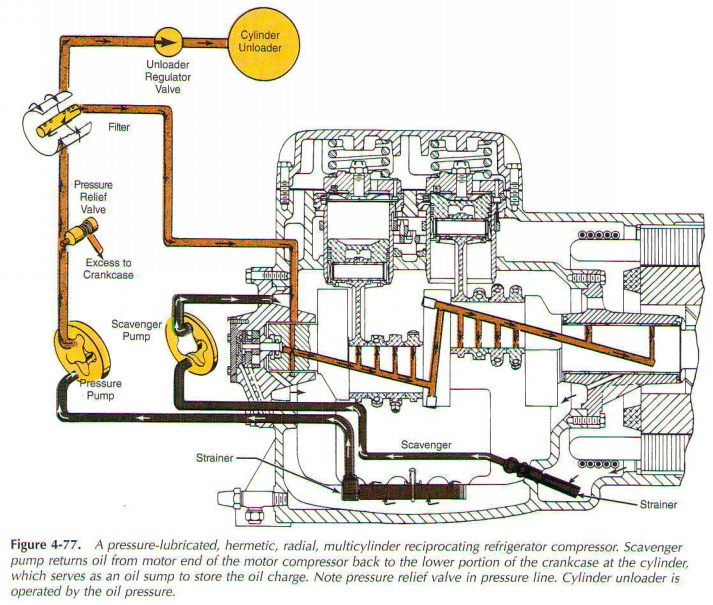

Oil pump, usually installed on one end of the crankshaft. Whenever you use, overload relief valve must be built in pump. This will protect it and the system against the pressure of the oil that are too high. Fig. 4-77 shows the oil road pressure-type of lubrication systems. Oil pump provides oil under pressure, for all bearing surfaces. More pressure from the compressor sometimes use a pressure-controlled electric switches. These will stop the unit, if the oil pressure drops too low. Sometimes you need to use some kind of discharge device. This allows the compressor to start easily, without steam pressure load cylinder.

In rotary compressor, continuous film of oil is needed on the cylinder, roller, and the blade surfaces. When the compressor is running, the oil is fed through the main bearings in the cylinder. The cylinder is thus the level of oil and half of the bearing caps. Larger units, and some smaller units use force-feed lubrication system. Some units use a separate oil pump. Some use the pumping action of the blades move in and out of their Windows.

..

|