Compressor

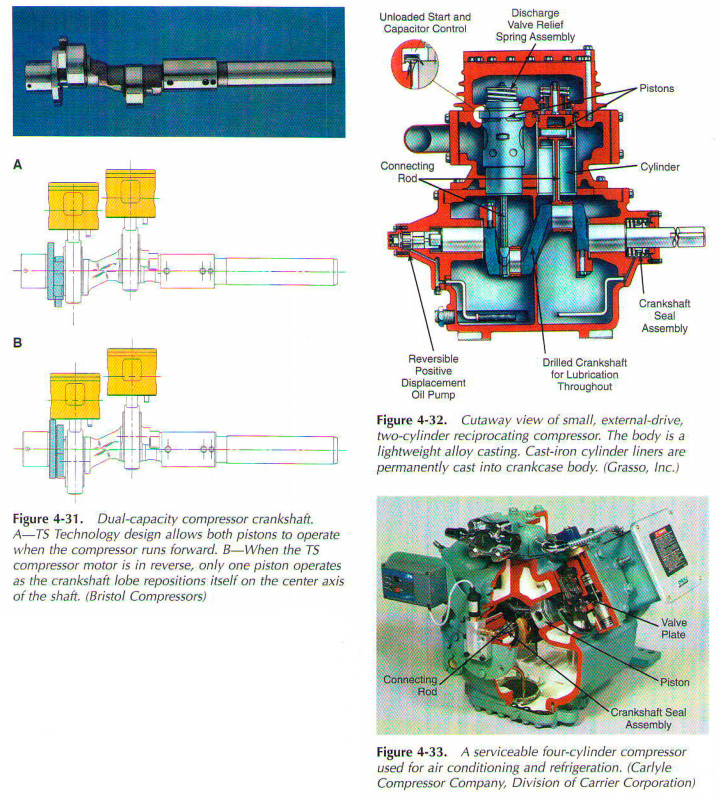

Compressor cylinders for external compressors, usually made of cast iron. Cast iron must be thick enough to prevent leakage. Some Nickel, as a rule, combine to give a casting desired density. Small compressors have fins cast cylinders to provide the best air cooling. Large compressors may have water jacket around the cylinders for cooling. Some compressors built or sleeves of cylinder liners, which can be replaced when worn.

As a rule, Carter is part of the same casting in the form of a cylinder. This practice reduces the number of connections that can leak. It also allows a closer match between the bearing crankshaft and cylinder. The main bearings ball. Construction is shown in Fig. 4-32. Side-by-Side arrangement of cylinders is typically used to open compressors. This compressor is intended for use by car Air conditioning. However, the same design may be used in other air-conditioning systems.

Hermetic compressors usually the cast iron cylinder.

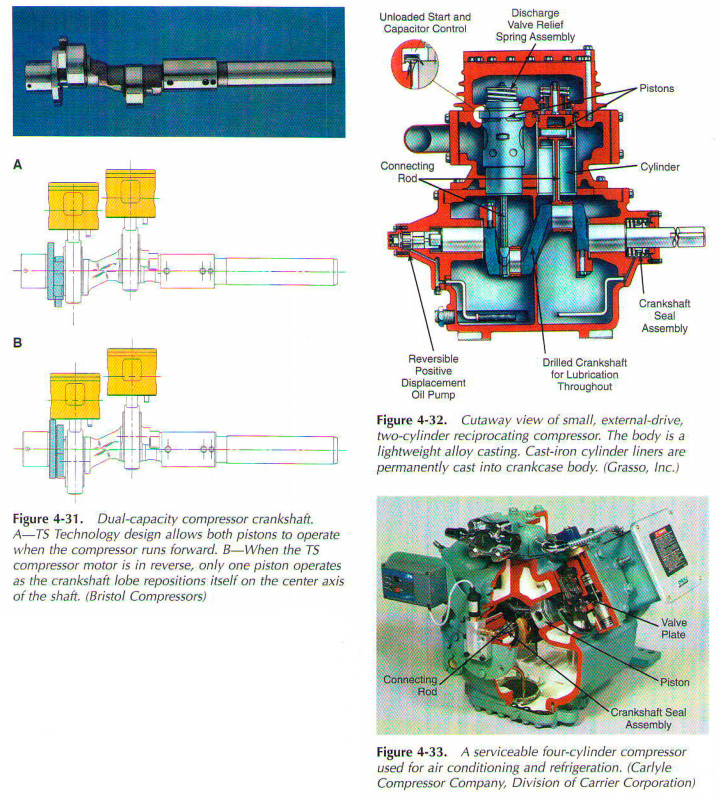

Some can be made of aluminum or other materials. Typical hermetic compressor cylinder shown in Fig. 4-27. Another type hermetic compressor Fig. 4-33. This bolts sealant that can be easily dismantled for maintenance.

Pistons and Piston Rings

Pistons external drive compressors, usually made of cast iron. In a small, high-speed hermetic compressors they cast aluminum. Smaller sizes are not piston rings. Temperature pistons rarely rises above $ 250F (12C). Thus, there are not many extension of either the cylinder piston. The pistons can be equipped with as little as .0002" (.0051 mm) clearance for each inches in diameter.

Less pistons have oil cut grooves in them. Fig. 4-34 illustrates commercial-type piston and connecting rod Assembly. It is equipped with piston rings. There are two types of piston rings. Top ring or rings are known as compression rings. The bottom is designed for control of oil flow in the past the piston. This oil ring. Piston rings are usually made of cast iron. Some bronze rings have been used, however. Rings must be installed into the groove as close as possible and still provides the movement. Ring is a complete circle with a gap in it. 45 conical or at an angle annular gap allows ring to push against the cylinder wall. The gap should be about .001" (.0254 mm) for each inches diameter of the piston.

Piston pins are made of case-hardened, high carbon steel earth exactly in size. They are hollow, to reduce weight. Piston pins, as a rule, full floating type. This means the pin freely in both rod, liners and pistons, sleeves. Piston designed to come as close to cylinder head not touching it. It weighs so much steam in the high-pressure side as possible.

When the piston is at top dead center (TDC) stroke, there was a very small gap. The clearance between the piston and the cylinder head about .010" .020" (254 law mm'.508 mm). The amount of space you have created is called free space.

.. ..

|

..

..