Engine Lubrication

External drive motors can be lubricated in different ways. It depends on the type of bearing used and the position of the engine. External-drive motors using bronze bushings, plain or sleeve, can be lubricated in two different ways:

- Wick system,

- Slip ring system.

In zvick system uses the well or reservoir, in the end, bell. Wick (cotton or wool s) carries oil from the well to the shaft sleeve. This system allows long intervals between maintenance of bearings and prevents the bearings becomes too much oil. This grease type, see Fig. 7-66.

Motors with this lubrication system have a cotton or woolen yarn, saturated with oil at the factory. However, before starting the engine, oil, Fig. 7-66. Motor end bearing, which uses the wick lubricator. Oil slingers and prevent leakage of oil in the motor or along the shaft of the motor. wells should be filled. Add the amount of oil designated or until the oil is in the lower level of oil Cup.

If the bearing is to be removed from the shaft or if the plug should be removed from the end of the bell, yarn must be lifted and installed on the support.

This prevents yarn being forced between the shaft and bearing replacement.

When replacing yarn package in equal amounts on each side of the bearing and the bearing spring the oil will push the cover yarn down on the shaft. Wick-lubricated bearings, must be anointed with one or two drops every six months.

In some large refrigeration motors with phase-wound method of lubrication. Brass ring lies on the motor shaft through the slit at the top of the bearing. The ring is large enough to dip in oil pocket below. As the motor shaft turns, ring, which turns slowly, and the wet part is used for lubrication of the bearing.

Be sure to check out of the ring at work on these engines. Use of average viscosity nondetergent oil, such as SAE 20 or SAE 30 (200 to 300 viscosity).

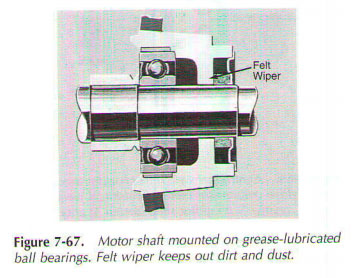

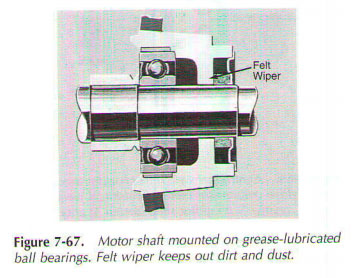

Some engines use ball bearings, as shown in Fig. 7-67. These bearings are grease lubricated. Most are sealed and do not require any service lubrication. Some rooms have a grease fitting (the so-called press fitting), set on the top of each bearing. Normal syringe is used for lubrication.

These engines, when new, have enough lubrication for bearings them for several months. A small amount of lubricant must be added every two or three months. Use a high-grade "middle" grease on a totally enclosed motors. Too much grease can lead to overheating of the bearings.

Bearing life depends, largely, on cleanliness. Use only clean the fat and keep the dirt out of the bearings. Clear all equipment before using a grease gun.

Most greases and oils are oxidized and will collect dirt during use. When the engine is running, restored, old grease should be discarded. The lubricated parts, should be thoroughly cleaned, and the new lubricant should be used.

Another method of lubrication are currently in use is ailless sleeve. In this arrangement, the shaft passes through the sintered (porous bronze) Bush. The sleeve was soaked with oil at the factors? Total tolerance between the shaft and the liner " less", " 001". This may have tolerance as little as .0003". As tolerance increases due to engine wear will be noisy. In oilless sleeve is considered permanently lubricated. It is often used for fan motors and other low-horsepower applications...

|