Ice cream

Ice cream is a product that has been designed with a mechanical refrigeration became available. Ice-cream mixtures are fats (not always milk), milk protein, sugar and additives such as emulsifiers, stabilizers, colorants, together with additional elements, such as fruit, nuts, chocolate pieces and others, depending on the appearance and taste. The presence of this mixture components means that the freezing process covers a wide range of temperatures, starting just below 0C and not finishing until 18C or below. The production process takes place in three main stages mixing, freezing to a plastic state and hardening

The basic mixture consists in liquid form, pasteurized, homogenized and cooling, using chilled water plate heat exchangers. It was then that the " aged " for several hours, and for this, it will be stored on 2-3C in the tank jacket, with chilled water shirt.

At the next stage freeze it quickly, with the introduction of controlled share of air to give him a light, edible texture. Cellular mix about 50% of air, 50% of the ice cream mixture on volume transmitted in one end of the trunk, which forms inside the flooded evaporator.

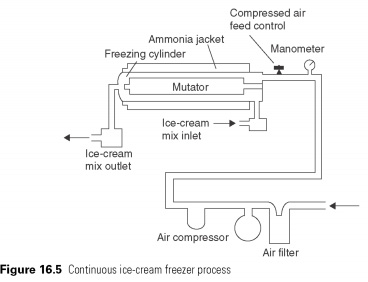

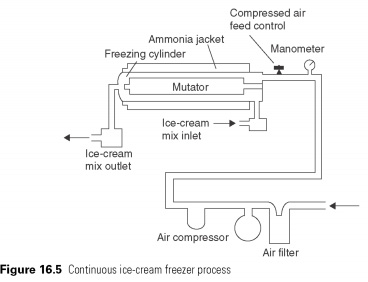

The mixture solidifies on the inner surface of the barrel and then scraped off the rotating stainless steel beater blade, and passes through the barrel of a continuous process of freezing, beatings and mixing. The most common refrigerant for ice-cream freezers continuous ammonia, which will be at the boiling point 35C to 30C. About half of the total heat freezing laughs, and ice cream leaves at about 5C, depending on the particular type of product. Continuous ice-maker process is shown in Fig. 16.5.

Ice cream is still plastic as it comes from the freezer, and she pulled final sales form - box, bath, safety Deposit box stick or product. Then he must be hardened cooling storage temperature 25C or below, during which half of it heat of freezing is removed. Stick products that fall into the trays and directly to the hardening of the tunnel. Fig. 16.6 shows four lanes sticks on their way hardening of the tunnel. This tunnel can handle up to 36 000 PCs/hour. Extrusion head is in the upper right corner. Flat boxes can be chilled between refrigerating plates, as shown in Fig. 7.14(a) although the tunnels are used most often.

An important factor of the final RIA, is that it should be as fast as possible to limit the size of the ice crystals in ice cream. Quick freezing implies a high heat transfer coefficient and, therefore, very low temperature refrigerant. A powerful stream of air 40C is common. Two stage compression systems are used.

Ice cream should be stored at low temperatures, up to the point of final consumption. If it is allowed to soften the entrained air bubbles may escape and original texture will be lost. If it is soft, and then froze again, hard, hard skin forms, making the product inedible. Ice cream should always be handled quickly passing through transit stages from the factory to the consumer.

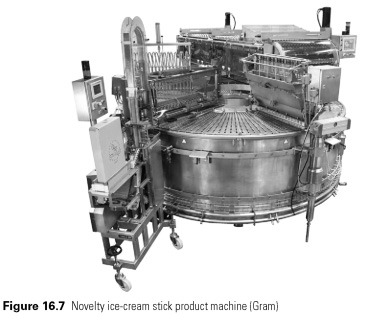

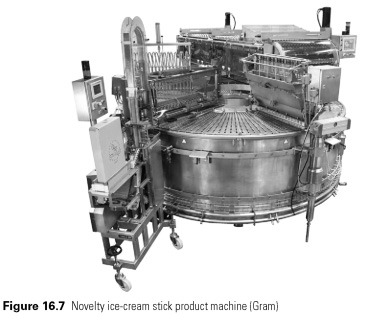

Novelties of the frozen products on a wooden stick produced in large quantities, and these products, frozen in metal forms/trays, which are immersed in salt tank with a built-in cooling coil or plate chiller. The novelty of the device, which can take various forms is shown in Fig. 16.7 . As ice and water ice products can be processed. Cooling, low temperature brine or carbon dioxide. Brine tank temperature the temperature, which can be between 28C and 35C, depending on the process. Forms are made of stainless steel or Nickel, and pass it into the ranks through the brine bath. Different layers of the confection can be built by allowing one outer layer freeze, sucking the unfrozen centre and filling mixed with the other. Sticks are inserted before the center freezes solid. Mold, finally, go through the defrosting in section warm brine production of the product with mold, and extractor grab bars sticks, remove the products and throw them in the packaging bags.

.. ..

|

..

..