Level-Master Control Oil and Halocarbon systems

With Halocarbon systems (Refrigerants 12, 22, 502 and other) oil and refrigerant blends (mixed together) under certain conditions. Oil is quite soluble in the liquid Refrigerant 12 and partially in the liquid Refrigerant 22 and 502. For example, for 5% (by weight) of the decision of typical naphthenic (on the basis of oil, oil) oil in liquid refrigerant, oil will remain in the solution down about 75F (59C) Refrigerant : 12 to about 0F (18C) Refrigerant 22, up to approximately 20F (7C) 502 Refrigerant. Depending on the type of oil and the share of oil currently, these figures can vary. However, based on the foregoing, it can be assumed that for the majority of Refrigerant-12 systems of oil and refrigerant is fully miscible with water in all temperatures normally encountered. However, at temperatures below 0F (18C) Refrigerant 22 and 5% of the oil concentration and temperature is below 20F (7C) 502 Refrigerant and 5% concentration of oil, liquid phase separation occurs. Oil-rich solution will

appear at the top and a refrigerant-rich solution will lie at the bottom of any relatively placid remote bulb chamber. Oil Halocarbon flooded evaporator can produce many results.

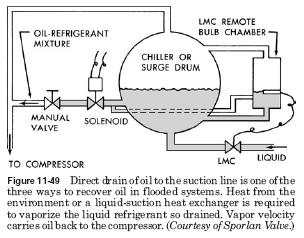

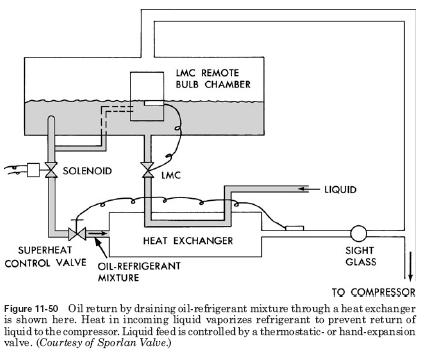

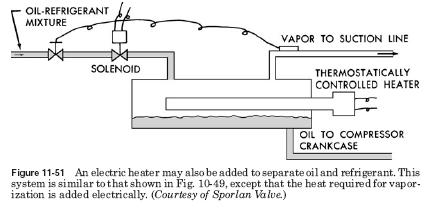

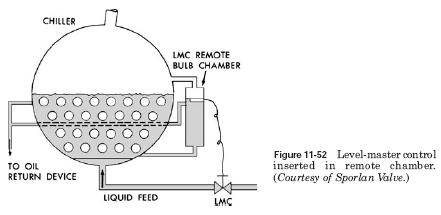

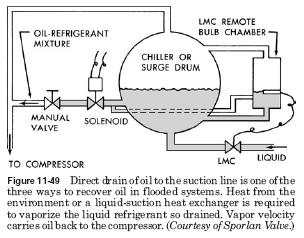

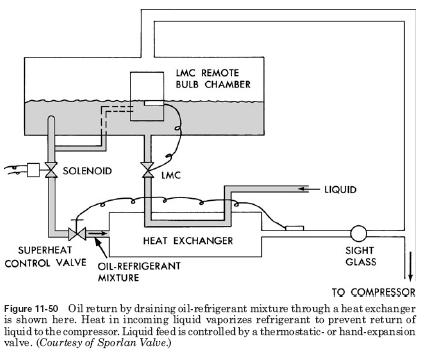

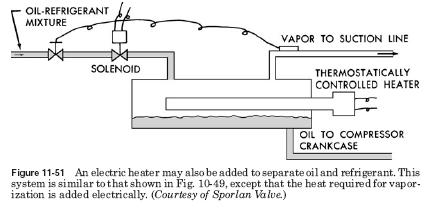

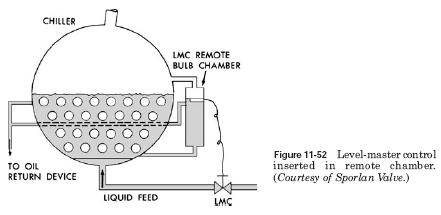

Oil as a contaminant will raise the temperature of boiling of the liquid refrigerant. For example, with refrigerant 12, boiling temperature increases by about 1F [(0.56C)] 5% of oil (by weight) in solution. As in ammonia systems, oil may confuse heat exchange surface with a subsequent loss in system performance. Oil can produce foaming and possible loss of the liquid in the suction line. Oil may also affect the liquid level control. With float valve, as a rule, you can expect that the level of liquid in the evaporator decreases with increasing concentration of oil in the float chamber. This is due to the difference in density between light oil in the chamber and a lower balance leg and heavier refrigerant/oil mixture in the evaporator. In the bottom column dense mixture in the evaporator balance will be higher oil column in remote camera and pipelines. It is like ЂњUЂќ tube manometer, other liquid in each leg. Master level control, heat-speed data transfer on the lamp decreases, producing overfeeding and possible flood-back. What can you do? First, the concentration of oil should be kept as low as possible in the evaporator, balancing and remote press the ball camera (if used). With refrigerant 12, with refrigerant oil homogeneous composition, it can be removed from almost any location in the cooler, balancing or remote camera, which is below the liquid level. With Refrigerants 22 502, drain must be at or just below the surface of the liquid, since the oil-bearing layer at the top. There are many kinds of oil-return device: Direct discharge to the suction line

Strain through a high-pressure liquid heat exchanger

Strain through a heat exchanger the heat supplied by the electric heater Draining directly to the suction line as shown in Fig. 11-49, this is the easiest way. However, the danger of possible flood-back to the compressor remains.

Drain through the heat exchanger, as indicated in Fig. 11-50, a popular method. The liquid refrigerant flood back problems to a minimum by the hot liquid of evaporation of liquid refrigerant in the oil/refrigerant mixture.

Using a heat exchanger with a liner, electric water heater, as shown in Fig. 11-51, a variation of the preceding method.

All the mechanisms of return was discussed, the solenoid valve should be installed in the drain line and agreed to close, if the compressor is not running. Otherwise, the liquid refrigerant can flow out of the low side of the crankcase during the cycle. If you insert the ball is installed directly in a surge or cooler, oil return is required only from this point. However, press the ball sometimes, located in remote Commerce, bound to a breather or chiller with liquid and gas balance line. Then the oil return must be made from both locations, as shown in Fig. 11-49, 11-50, and 11-52.

..

|